Multi-Layer Mesh With Rim: Enhancing Efficiency in Extrusion Processes

At Anping County Ansheng Wire Meshes Product Co., Ltd., we specialize in providing high-quality multi-layer mesh with rim solutions tailored for industrial extrusion applications. Our advanced extruder screens and screen extrusion technologies ensure optimal performance, durability, and precision for manufacturers across various industries.

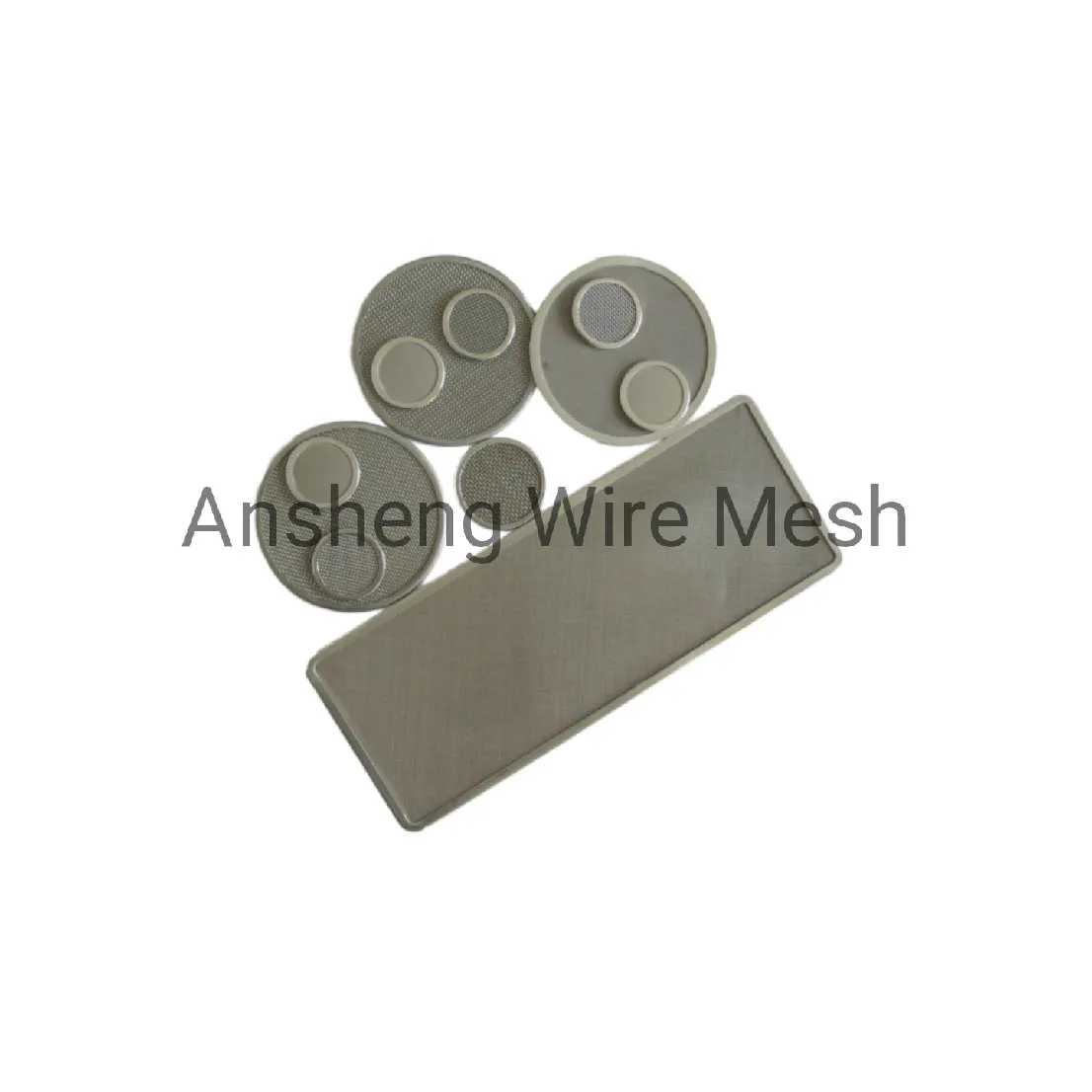

Product Overview

The multi-layer mesh with rim is a critical component in extrusion systems, designed to filter out impurities and ensure consistent material flow. Our product combines multiple layers of fine mesh with a reinforced rim, offering superior structural integrity and resistance to deformation under high-pressure conditions. This design not only enhances filtration efficiency but also extends the service life of the screen, reducing downtime and maintenance costs for businesses.

Key Features and Benefits

- Advanced Multi-Layer Design: The multi-layer structure effectively captures fine particles, ensuring the purity of extruded materials.

- Reinforced Rim: The durable rim prevents distortion during installation and operation, maintaining the screen's shape under high stress.

- Customizable Specifications: We offer tailored solutions to meet the unique requirements of different extrusion processes.

- High Resistance to Wear: Constructed from premium materials, our screens withstand harsh industrial environments without compromising performance.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Stainless steel, aluminum, or other alloys based on application needs |

| Mesh Count | 10-200 mesh (customizable) |

| Thickness | 0.5-3.0 mm (adjustable) |

| Working Temperature | -20°C to 800°C (depending on material) |

| Surface Finish | Smooth, corrosion-resistant, and easy to clean |

Industry Applications

Our aluminum extrusion screen frame and fly screen extrusion solutions are widely used in the following sectors:

- Plastics and Polymers: Ensuring uniform extrusion of pellets and filaments.

- Metal Processing: Filtering molten metal to prevent defects in castings.

- Food and Beverage: Maintaining hygiene standards during packaging and processing.

- Chemical Manufacturing: Controlling impurities in liquid and powder materials.

Market Demand and Industry Challenges

The demand for high-performance extrusion screens has surged due to the need for precision and efficiency in modern manufacturing. However, traditional screens often face challenges such as clogging, wear, and inconsistent filtration. Our multi-layer mesh with rim addresses these issues by combining advanced materials with an innovative design, ensuring reliable operation even in the most demanding environments.

Company Expertise and Innovation

With over a decade of experience in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a leader in extruder screen technology. Our state-of-the-art R&D facilities and dedicated team of engineers continuously develop cutting-edge solutions to meet evolving market needs. We hold multiple patents for our screen extrusion processes, ensuring our products remain at the forefront of industrial filtration technology.

Proven Performance and Customer Testimonials

Our clients have reported significant improvements in production efficiency and product quality after adopting our multi-layer mesh with rim. One customer from the plastics industry noted, "The durability and precision of Anping's screens have reduced our maintenance costs by 40% and increased output by 25%." Another user in the metal processing sector highlighted, "The reinforced rim design has prevented screen deformation, ensuring consistent extrusion quality."

Implementation and Customization

We provide comprehensive support for integrating our multi-layer mesh with rim into existing extrusion systems. Our technical team offers on-site consultations and customized solutions to optimize performance for specific applications. Whether you require a standard product or a tailored design, we ensure seamless compatibility with your equipment.

Quality Assurance and Compliance

All our products comply with international standards, including ISO 9001 and ASTM. Rigorous testing is conducted at every production stage to guarantee reliability and safety. Our multi-layer mesh with rim is designed to meet environmental regulations, ensuring minimal impact on the ecosystem while maintaining high operational efficiency.

Logistics and Packaging

We offer bulk packaging solutions to accommodate large-scale orders, with each unit securely sealed to prevent damage during transit. Our logistics partners ensure timely delivery worldwide, with tracking systems in place to monitor shipments. For more details, visit our company page.

After-Sales Support and Technical Services

At Anping County Ansheng Wire Meshes Product Co., Ltd., we are committed to providing exceptional customer service. Our dedicated support team is available 24/7 to address technical inquiries, provide usage guidance, and assist with product customization. We also offer training sessions to help clients maximize the benefits of our multi-layer mesh with rim.

Contact Us

For more information or to place an order, please contact us at:

- Phone: +86-312-7212345

- Email: sales@anshengfilterscreen.com

- Website: www.anshengfilterscreen.com

FAQ

Q: What materials are used in the construction of the multi-layer mesh with rim?

A: We use high-grade stainless steel, aluminum, or other alloys, depending on the application requirements.

Q: Can the mesh size be customized?

A: Yes, we offer a range of mesh sizes from 10 to 200 mesh, with custom options available.

Q: How long does it take to deliver bulk orders?

A: Delivery time varies based on the order quantity and destination. Our logistics team ensures prompt delivery with real-time tracking updates.

Conclusion

Invest in high-quality multi-layer mesh with rim from Anping County Ansheng Wire Meshes Product Co., Ltd. to elevate your extrusion processes. With our innovative solutions, you can achieve greater efficiency, cost savings, and operational excellence. Visit our company page today to learn more.

Post time: Jul . 21, 2025 12:40