Introduction to Mesh Filtration Technology

The industrial filtration market has seen remarkable growth over the past decade, with the global mesh filter market projected to reach $6.8 billion by 2027, according to industry reports. At the core of this technological advancement is the fundamental screen filter technology that has been refined over decades to meet increasingly demanding industrial requirements.

Modern mesh filter applications range from basic particle separation in water treatment plants to critical aerospace components and biomedical devices. This versatility comes from the ability to precisely engineer screen meshes with specific opening sizes, wire diameters, and weave patterns to meet exact filtration requirements.

Anping County Ansheng Wire Meshes Product Co., Ltd.

Leading the innovation in wire mesh solutions since 2003, Ansheng specializes in high-quality mesh filter and screen filter products with superior durability and precise specifications.

Contact Information

Phone: +86-0318-7978378

Mobile: +8615131832545

Email: sales@anshengwiremesh.com

Address: No.346 Xinying East Street, Anping County, Hebei. China

Visit Official WebsiteTechnical Support

Our engineering team provides comprehensive technical support for:

- Material selection guidance

- Mesh specification analysis

- Custom weave design

- Filtration efficiency testing

Quality Certifications

- ISO 9001:2015 Certified

- ASTM E11 Compliance

- DIN Standards Certification

- RoHS Compliance

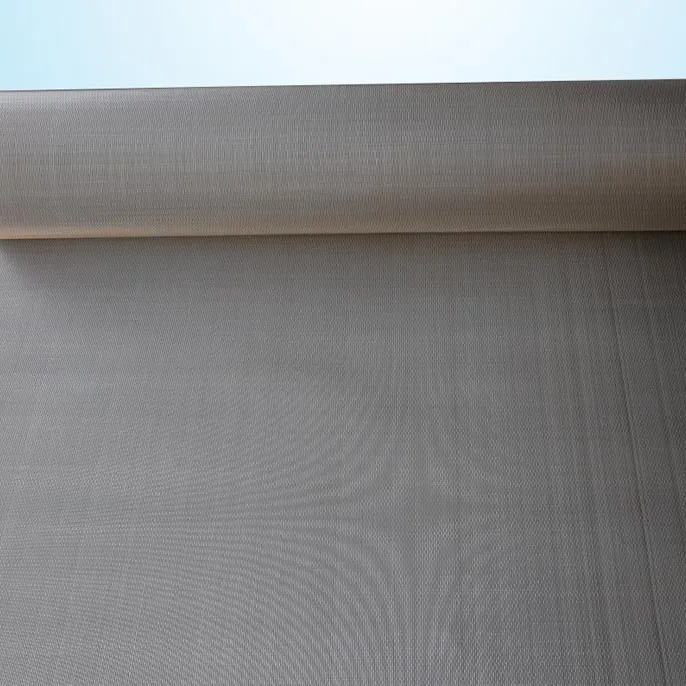

Iron Plain Weave Wire Mesh

Premium Filtration Solution

Our flagship Iron Plain Weave Wire Mesh represents decades of manufacturing expertise in screen filter technology. Crafted from high-grade low-carbon steel, this versatile mesh filter solution offers exceptional strength-to-weight ratio with precise openings that can be customized to specific application requirements.

Technical Specifications

- Material: Low-carbon steel (ASTM A366/A568)

- Mesh Range: 9-80 mesh (available with custom specifications)

- Wire Diameter: 0.13mm-0.8mm (±0.01mm tolerance)

- Standard Width: 0.915m-1.3m

- Standard Length: 30m rolls (custom lengths available)

- Weave Types: Plain weave, herringbone weave, Dutch weave

- Surface Treatment: Black finish, galvanized, PVC coated

Technical Parameters of Modern Mesh Filters

| Parameter | Standard Range | Premium Specifications | Measurement Standards | Application |

|---|---|---|---|---|

| Mesh Count | 5-400 mesh | Up to 500 mesh (ultrafine) | ASTM E11, ISO 9044 | Standard to precision filtration |

| Wire Diameter | 0.05mm-2.0mm | 0.02mm-3.0mm | ASTM A480 | Determines strength & durability |

| Aperture Size | 125μm-4000μm | 20μm-5000μm | ASTM E1616 | Filtration accuracy |

| Open Area % | 15%-60% | 10%-70% | ISO 9044 | Flow rate & efficiency |

| Tensile Strength | 300-1000 MPa | Up to 1500 MPa | ASTM A370 | Structural applications |

| Material Thickness | 0.1mm-5mm | 0.08mm-8mm | ISO 3611 | Industrial durability |

Technical Visualization & Trends

Industrial Applications

Key Industrial Applications

The versatility of modern mesh filter technology allows it to serve critical functions across multiple industries:

Chemical Processing

Chemical-resistant Dutch weave meshes made from 316L stainless steel provide filtration under extreme pH conditions and high temperatures. With an ability to filter particles down to 5 microns, these screen filters are essential for catalyst recovery and final product purification.

Water Treatment

Municipal water facilities increasingly use multilayer mesh filter systems for tertiary treatment. The progressive filtration system begins with coarse mesh (200-400 micron) for initial screening, followed by finer meshes (75-150 micron) that capture microorganisms and suspended solids while maintaining optimal flow rates.

Mining & Minerals

Heavy-duty filter meshes manufactured from abrasion-resistant materials with reinforced weaves handle extreme slurry flows with solids concentrations up to 50%. The strategic positioning of mesh filter systems in mineral processing circuits can reduce downstream processing requirements by 20-40%.

Professional FAQ: Mesh Filter Technology

What wire materials offer the best corrosion resistance for mesh filters?

For maximum corrosion resistance in aggressive environments, 316/L stainless steel is the standard choice, with Alloy 20 and Hastelloy recommended for specialized chemical applications. For extreme conditions, titanium mesh offers unparalleled resistance with a strength-to-weight advantage. Electro-polished finishes further enhance corrosion resistance by creating a passive chromium oxide layer.

How do we calculate mesh opening size versus wire diameter?

The relationship follows: Aperture = (25.4 / Mesh Count) - Wire Diameter. For precise measurements, laser micrometers should be used following ASTM E11 standards. The coefficient of variation should remain below 3% across the mesh width. Critical applications require statistical process control maintaining ±2% tolerance from nominal values.

What installation methods maximize mesh filter longevity?

Proper tensioning is critical – typically maintained at 200-400 N/m depending on wire diameter. Frame-mounted installations require continuous perimeter clamping with torque-controlled fasteners (18-25 Nm for M8 bolts). Support grids must maintain spacing at no more than 75% of the unsupported span tolerance to prevent deflection-induced fatigue failures.

How does Dutch weave differ structurally from plain weave?

Dutch weave employs a warp/weft diameter differential (typically 1.5-3:1 ratio) with finer weft wires tightly packed. This creates an asymmetric structure where larger warp wires determine strength while fine weft wires control precision filtration. Triple-layered Dutch weaves can achieve absolute filtration down to 5 microns while maintaining high flow rates.

What cleaning methods preserve mesh integrity?

Ultrasonic cleaning (40-80 kHz) works well for routine particulate. For caked materials, backflush systems should operate at ΔP 1.5-2.5 bar. Chemical cleaning requires pH compatibility assessments - citric acid solutions (5-10%) for mineral scales, EDTA-based solutions for metallic contaminants. Steam sterilization at 121°C/15psi can be performed on 300-series stainless meshes.

How to determine replacement timing for mesh filters?

Performance-based replacement is ideal: When flow rates decrease below 70% of initial capacity at constant ΔP. End-of-life indicators include: visible wire deformation >3% of diameter, >15% increase in opening size, or fatigue cracks identified by dye penetrant inspection. Routine pressure differential records provide predictable maintenance scheduling.

What certifications ensure mesh quality compliance?

Material Certifications: ASTM A480 with full traceability. Dimensional Compliance: ASME MSE-4 for wire diameter and aperture size. Performance Validation: ISO 16889 multi-pass testing for beta ratios ≥75. Industry-specific: FDA CFR 21 for food contact, USP Class VI for pharmaceutical, ASME BPE for bioprocessing. Manufacturer-specific quality management: ISO 9001 and ISO 14001.

Industry References & Research

- Filtration & Separation Journal: "Advances in Woven Mesh Technology for Nanofiltration Applications" (https://www.filtsep.com/technologies/woven-filters/)

- ASME Publication: "Standardized Testing Methods for Industrial Screen Filters" (https://www.asme.org/codes-standards)

- Journal of Materials Engineering: "Corrosion Resistance of Advanced Alloy Meshes in Harsh Chemical Environments" (https://doi.org/10.1016/j.jmatprotec.2021.117206)

- European Filtration Society: "Optimizing Mesh Selection for Sustainable Water Treatment" (https://www.efs-filtration.org/research)

- ASTM Standard E11-20: "Specification for Wire Cloth and Sieves for Testing Purposes" (https://www.astm.org/e0011-20.html)

Technical Consultation Available

Contact our engineering team for application-specific mesh filter solutions

sales@anshengwiremesh.com | +86-0318-7978378

Request Product SpecificationsPost time: Jul . 25, 2025 16:01