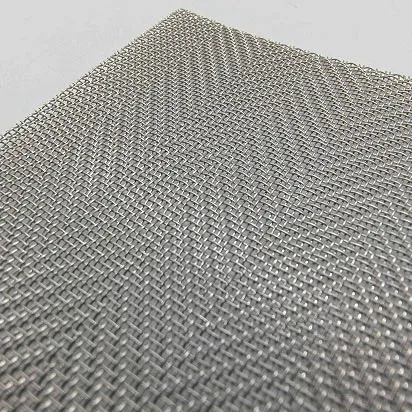

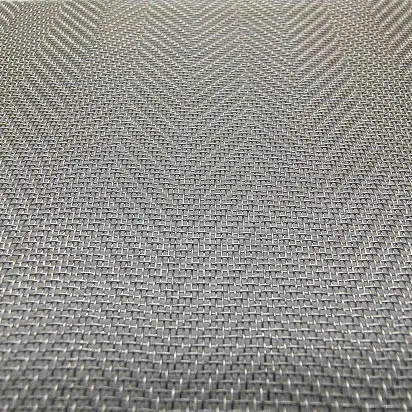

Stainless Steel Herringbone Weave Wire Mesh: Field Notes, Specs, and Real-World Use

If you work in filtration, extrusion, or frankly any process line that hates downtime, you’ve probably bumped into herringbone mesh more times than you can count. It’s one of those patterns that looks deceptively simple and then surprises you on the line: stable under pressure, less prone to deformation than plain weave, and—when you spec it right—remarkably cleanable. I’ve seen buyers move from 304 to 316L just to squeeze out corrosion life, and honestly, I can’t blame them.

What sets the pattern apart

The staggered “V” formation in herringbone mesh distributes load laterally. In practice, that means steadier pore geometry when the differential pressure spikes. Not magical, just well-engineered weaving with a little forgiveness.

Core specifications (typical, field-proven)

| Parameter | Specification |

|---|---|

| Material grades | SS 201, 304, 316, 316L (others on request) |

| Mesh range | 30–60 mesh |

| Wire diameter | ≈0.12–0.40 mm |

| Width | 0.915–2.0 m standard; custom widths available |

| Length | 30 m per roll (typical) |

| Weave options | Herringbone, plus plain, twill, Dutch, reverse Dutch |

| Approx. retention | ≈250–600 μm (real-world use may vary) |

| Temp resistance | Up to ≈800°C (grade-dependent) |

Process flow (how it’s actually made)

- Material prep: coil selection (201/304/316/316L) with heat number traceability (EN 10204 3.1).

- Wire drawing and intermediate annealing for ductility control.

- Weaving: dedicated looms set to the herringbone pattern; on-loom tension checks.

- Calendering (as needed) to tune thickness and stability; then stress-relief.

- Cleaning + passivation per ASTM A967; rinse to conductivity threshold.

- Inspection to ISO 9044 / ASTM E2016: mesh count, aperture, flatness, burrs.

- Packaging: kraft + PE wrap; edge guards; labeled cores for lot traceability.

Where it’s used (and why teams like it)

Common installs: polymer extrusion screens, catalyst support packs, edible oil filtration, craft brewing, pulp and paper, and upstream chemical processing. One brewery ops manager told me they switched to 316L herringbone mesh after cleaning cycles were chewing up plain weave. Result? Fewer press plate reworks and predictably cleaner runs. Not glamorous, but profitable.

Test data and certifications

- Dimensional tolerance: mesh count within ±3%, aperture uniformity within ≈±8% (lot average).

- Tensile strength (wire): ≈600–1000 MPa depending on grade and draw.

- Corrosion: 316L after ASTM B117 salt spray >200 h with post-passivation—no red rust noted.

- Certs available: ISO 9001, RoHS/REACH material declarations, EN 10204 3.1 MTRs.

Vendor snapshot (quick comparison)

| Vendor | Grades | Lead time | MOQ | Indicative price | Notes |

|---|---|---|---|---|---|

| Ansheng (Anping, Hebei; No.346 Xinying East St.) | 201/304/316/316L | ≈7–15 days | 1 roll (30 m) | ≈$6–14/m² (spec-dependent) | Tight QC; custom widths to 2 m |

| Vendor A | 304/316 | ≈10–20 days | 2–3 rolls | ≈$7–16/m² | Good for small batches |

| Vendor B | 316/316L | ≈15–25 days | 1 roll | ≈$8–18/m² | Focus on high-corrosion apps |

Customization and service life

Custom slit widths, layered screen packs, edge welding, discs, and pre-flattening are common asks. In non-caustic food service, 304 herringbone mesh can run 3–6 years; 316L in chlorides might still look respectable after 5–8 with sane CIP chemistry. Your mileage, as always, depends on cleaning and pressure cycles.

A quick case

A polymer recycler swapped in 50-mesh 316L herringbone mesh packs. After a month, pressure-drop at 0.5 m/s air equivalent dropped from ≈42 Pa to ≈27 Pa per layer, and changeout intervals stretched by 20–30%. Not world peace, but it paid for itself in a quarter.

Curious? The Stainless Steel Herringbone Weave Wire Mesh ships from Anping County, Hebei, China—where this craft is practically a hometown tradition.

Authoritative references

Post time: Oct . 08, 2025 22:55