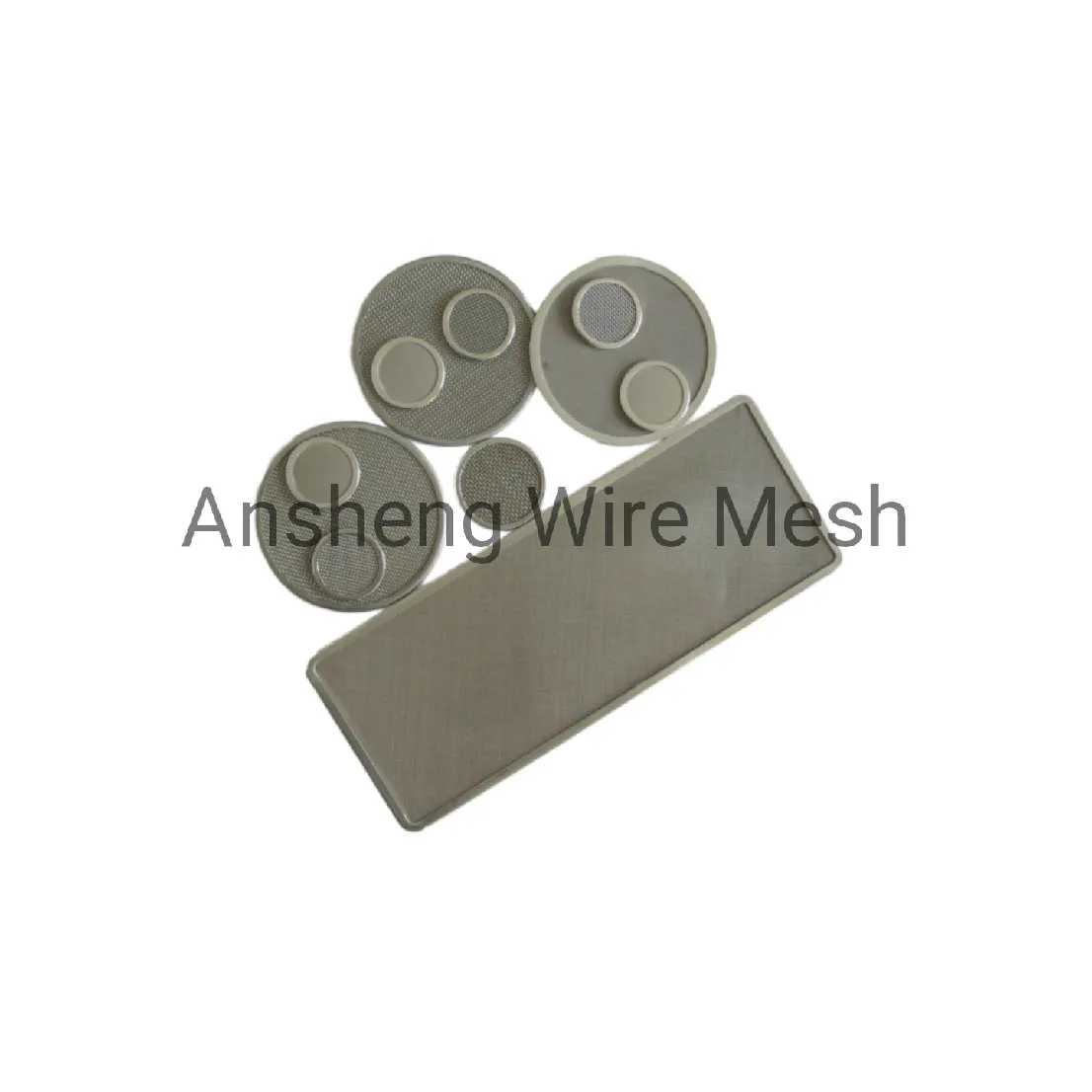

What I’m Seeing in Extrusion Filtration: Multi-Layer Mesh With Rim, Up Close

If you work around plastics, rubber, or compounding lines, you already know how quietly crucial extruder screens are. They’re not glamorous, but they save barrels, screws, and customers’ patience. Lately I’ve been spending time with Multi-Layer Mesh With Rim packs coming out of Anping, and—surprisingly—there’s been real progress in consistency and edge integrity. To be honest, that’s where downtime sneaks in.

Quick context: Ansheng’s Multi-Layer Mesh With Rim is built in No.346 Xinying East Street, Anping County, Hebei, China—yep, the wire-mesh capital. Materials include SS304/201/316/316L, low-carbon steel, galvanized, with rims in stainless or aluminum. Shapes? Circle, square, oval, kidney-shaped, rectangles, and outright irregulars. I’ll get into specs and test data in a moment.

Industry trends (and what lines are asking for)

- Higher contamination loads from recycled feeds—meaning denser, multi-layer extruder screens and more gradient stacks.

- Traceability: heat-batch, steel grade, mesh verification (ISO/ASTM references below).

- Edge reliability: secure, smooth rims to stop snagging during swaps—real operators notice this.

Product snapshot and specs

Type options: seamed and unseamed. Weaves: plain, twill, dutch. Mesh scope: 1–635 mesh. Sizes: 5–500 mm OD. Property claims: uniform mesh size, secure/smooth edging.

| Parameter | Range / Options | Notes (real-world may vary) |

|---|---|---|

| Mesh layers | 1–7 layers typical | Gradient stacks (e.g., 10/20/40/80/120 mesh) |

| Materials | SS304, SS201, SS316/316L, low-carbon, galvanized | 316L for corrosive/food contact; mill certs on request |

| Rim | Stainless or aluminum | Rolled or spot-welded; smooth edge to reduce snag |

| Diameter / shape | 5–500 mm; circle/square/oval/kidney/irregular | OD/ID tolerance ≈ ±0.10–0.20 mm |

| Testing | Aperture (ISO 9044), mesh (ASTM E2016) | Pull test on rim; visual/weld integrity; burr check |

Internal test data (representative): ΔP at 120 mesh, 3-layer SS316L, air at 20°C, 1 m/s face velocity ≈ 220–260 Pa; bubble leak on welded rim: none at 0.3 MPa; service life in PE blown film with 6–8% fines: 80–140 hours per pack before changeover. Your polymer and contamination will push that up/down.

Where they’re being used

- Film and sheet lines (PE, PP, PET): consistent melt and fewer gels; extruder screens as sacrificial filters before breaker plates.

- Recycling and compounding: masterbatch, fillers, reclaimed PCR with higher ash.

- Food-grade and pharma intermediates: 316L meshes with documented traceability.

- Hot-melt adhesives, rubber, and fiber spinning: tighter weaves (dutch) to catch fines.

Why multi-layer packs with rims?

- Smoother changeovers (no frayed edges, fewer operator cuts).

- Gradient filtration—capturing larger particles first to extend screen life.

- Lower variability: many customers say melt spikes drop after switching to rimmed packs.

Vendor comparison (what buyers usually check)

| Vendor | Mesh range | Rim options | Lead time | Certifications | Price index |

|---|---|---|---|---|---|

| Ansheng (Anping) | 1–635 | SS, Aluminum | 7–15 days typical | ISO 9001, RoHS/REACH | 1.0 |

| Vendor A (EU) | 5–400 | SS | 10–20 days | ISO 9001 | 1.3–1.5 |

| Vendor B (US) | 10–500 | SS, Aluminum | 5–12 days | ISO 9001 | 1.4–1.7 |

Relative, indicative. Real-world use may vary with alloy, layer count, and tolerances.

Process flow and QC (how these packs are built)

Material receipt with EN 10204 3.1 certs → mesh cutting (laser/press) → stacking per spec (gradient) → rim forming (rolling or stamped ring) → spot weld or seam → deburr/polish edges → aperture verification (ISO 9044), mesh conformance (ASTM E2016) → rim pull/peel test → visual inspection → packaging with batch IDs. Typical service life: 60–180 hours in standard film applications; higher with cleaner feed.

Customization and quick wins

- Shapes: kidney or notched rings to match breaker-plate ports.

- Marking: laser-etched mesh codes help operators stack correctly.

- Food-contact builds: SS316L meshes and rims, documentation aligned to FDA 21 CFR parts where applicable.

Mini case notes

- PE blown film line cut changeovers by ≈18% switching to 5-layer rimmed extruder screens (120→80→40→20→10 mesh).

- Recycling compounding (PP + CaCO3): gel count down ~12% after moving to dutch-weave top layer.

- Hot-melt adhesive: smoother melt pressure (±3%) with tighter OD tolerance and aluminum rim to reduce thermal mass.

If you’re auditing suppliers, ask for ISO 9001 certs, mesh conformance to ASTM E2016, aperture reports to ISO 9044, and batch traceability. It sounds fussy; it saves headaches.

Citations

- ASTM E2016 – Standard Specification for Industrial Woven Wire Cloth. https://www.astm.org/e2016

- ISO 9044:2020 – Industrial wire screens and woven wire cloth. https://www.iso.org/standard/70313.html

- FDA 21 CFR (Materials in contact with food), general reference. https://www.ecfr.gov

- ISO 9001:2015 – Quality management systems. https://www.iso.org/iso-9001-quality-management.html

Post time: Oct . 19, 2025 16:30