extruder screens, screen extrusion, extrusion screens, aluminum extrusion screen frame, fly screen extrusion is a key solution in the Mechanical equipment and components industry, specifically within Filtering and separation equipment and Extruder filter screen. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- extruder screens, screen extrusion, extrusion screens, aluminum extrusion screen frame, fly screen extrusion Overview

- Benefits & Use Cases of extruder screens, screen extrusion, extrusion screens, aluminum extrusion screen frame, fly screen extrusion in Extruder filter screen

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Mechanical equipment and components

- Conclusion on extruder screens, screen extrusion, extrusion screens, aluminum extrusion screen frame, fly screen extrusion from Anping County Ansheng Wire Meshes Product Co., Ltd.

extruder screens, screen extrusion, extrusion screens, aluminum extrusion screen frame, fly screen extrusion Overview

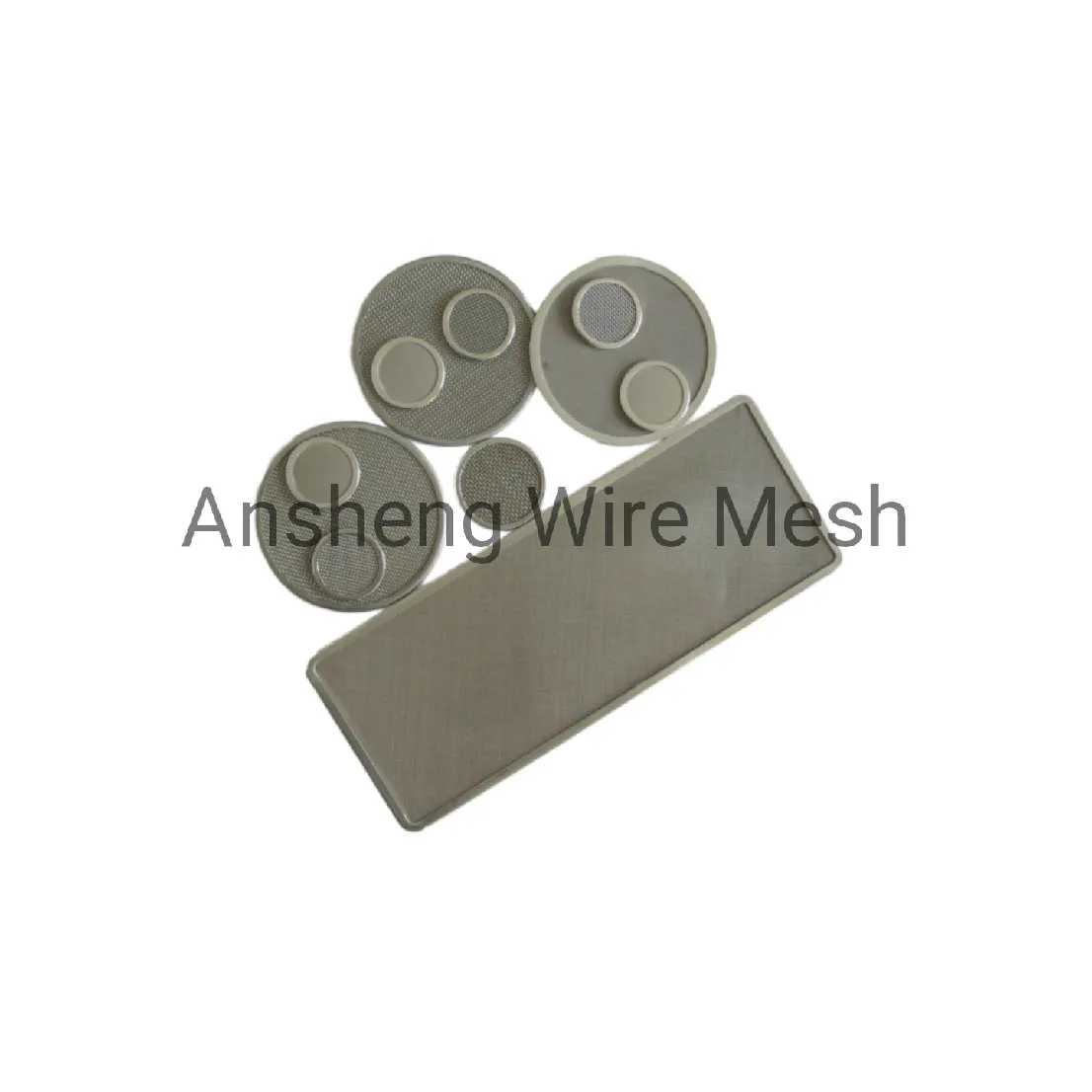

Extruder screens—often assembled as multi-layer screen packs with a protective rim—are vital filtration components that remove gels, metal fines, paper, wood, and other contaminants from molten polymers during screen extrusion and pelletizing. By stabilizing backpressure and protecting the melt pump and die, extrusion screens help manufacturers improve melt homogenization, surface finish, and throughput. Typical constructions include 1–5 layers of stainless steel wire cloth (commonly SS304/SS316) in mesh counts from roughly 20 to 150 for general plastics, with finer meshes available for specialty applications. The aluminum extrusion screen frame or stainless-steel rim enhances rigidity, seals the edges, and enables quick, repeatable installation in manual and automatic screen changers.

Anping County Ansheng Wire Meshes Product Co., Ltd. manufactures precision multi-layer mesh with rim in round, oval, and custom shapes, with diameters commonly ranging from small laboratory sizes to large industrial formats. Edge welding or crimping ensures dimensional stability at temperature. In both primary polymer production and recycling, fly screen extrusion profiles (aluminum extruded frames) can be adapted as robust rims for filter packs, delivering consistent sealing performance. For technical details and configurations, see the product page: Multi-layer Mesh with Rim.

Benefits & Use Cases of extruder screens, screen extrusion, extrusion screens, aluminum extrusion screen frame, fly screen extrusion in Extruder filter screen

Across blown film, cast film, sheet and pipe extrusion, fiber spinning, compounding, and recycling, extruder screens deliver clean melt and stable line performance. Multi-layer extrusion screens combine coarse and fine meshes to trap a wide contaminant spectrum while maintaining controlled backpressure. This structure extends run time between changeouts and helps protect high-value components. In recycling lines, where contaminant load is higher, rimmed screen packs are indispensable for safeguarding gear pumps and dies while preserving output quality.

Key advantages include precise mesh selection, robust temperature resistance, and a secure seal thanks to an aluminum extrusion screen frame or stainless rim. The framed design reduces edge fraying, prevents bypass, and enables faster, safer handling during hot swaps. Anping County Ansheng Wire Meshes Product Co., Ltd. supports custom layering strategies (e.g., 60/80/100 mesh combinations) to match specific resin viscosities and contamination profiles. Whether you’re running virgin resin or PCR blends, the right screen extrusion configuration helps balance filtration efficiency, melt pressure, and energy consumption—ultimately improving yield and product consistency.

Cost, Maintenance & User Experience

Total cost of ownership for screen packs is driven by filtration stability, changeover frequency, and scrap reduction. Well-built rimmed extruder screens can lower unplanned downtime by resisting deformation and edge leakage, which reduces off-spec product and keeps the line on-ratio. While initial unit costs vary by mesh count, layer stack, and frame material, longer service intervals and predictable pressure profiles translate into a compelling ROI for high-throughput lines.

From a maintenance perspective, best practices include storing screens dry and flat, verifying orientation during installation, and tracking differential pressure to anticipate changeouts before quality drifts. Many B2B users value burr-free rims, clean welds, and consistent mesh alignment that speed changeovers and minimize operator risk. Anping County Ansheng Wire Meshes Product Co., Ltd. focuses on dimensional accuracy and repeatability so packs fit seamlessly in manual slide plates or continuous screen changers. Customers in filtering and separation equipment applications report smoother startups and fewer die streaks when moving to tightly specified, multi-layer screen extrusion assemblies.

Sustainability & Market Trends in Mechanical equipment and components

The push for higher recycled content, evolving regulations, and brand sustainability targets are reshaping extrusion operations. As PCR percentages rise, contaminant loads increase, making robust extrusion screens essential for maintaining quality without excessive energy use. Durable, multi-layer packs enable longer runs and fewer purge cycles—supporting lower waste and improved line efficiency. Stainless steel meshes and aluminum rims are widely recyclable, aligning with circular economy goals and responsible material stewardship.

Market trends include finer filtration for film and fiber, greater adoption of automatic screen changers, and data-driven maintenance using pressure and quality analytics. Anping County Ansheng Wire Meshes Product Co., Ltd. is investing in precise mesh processing, tighter tolerances, and responsive customization to help processors meet regulatory and customer expectations. With attention to material traceability and packaging that reduces waste, the company positions its extruder screens and aluminum extrusion screen frame solutions as both performance-forward and eco-conscious choices for modern production lines.

Conclusion on extruder screens, screen extrusion, extrusion screens, aluminum extrusion screen frame, fly screen extrusion from Anping County Ansheng Wire Meshes Product Co., Ltd.

Extruder screens are mission-critical for clean melt, stable backpressure, and consistent output across screen extrusion, film, sheet, and recycling applications. Multi-layer extrusion screens with an aluminum extrusion screen frame deliver reliable sealing, fast changeovers, and long service life—key to quality and uptime. Anping County Ansheng Wire Meshes Product Co., Ltd. provides dependable, customizable solutions that align with your productivity and sustainability goals.

Contact us: email: sales@anshengwiremesh.com

Visit our website: https://www.anshengfilterscreen.com

Post time: Oct . 09, 2025 07:10