- Industry growth statistics and market potential

- Technical advantages over traditional materials

- Leading manufacturer comparison charts

- Customization options and engineered solutions

- Real-world application case studies

- Material innovation and manufacturing excellence

- Future applications and industry evolution

(expanding metal company)

The Expanding Metal Company Landscape in Modern Construction

The expanding metal industry continues robust growth as infrastructure demands increase globally. Market research indicates annual growth exceeding 5.8% through 2028, reaching an estimated $4.2 billion valuation. Expanding metal sheets specifically show 6.7% year-over-year demand increase across industrial sectors, with expanding metal company

solutions becoming integral to architectural, security, and manufacturing applications.

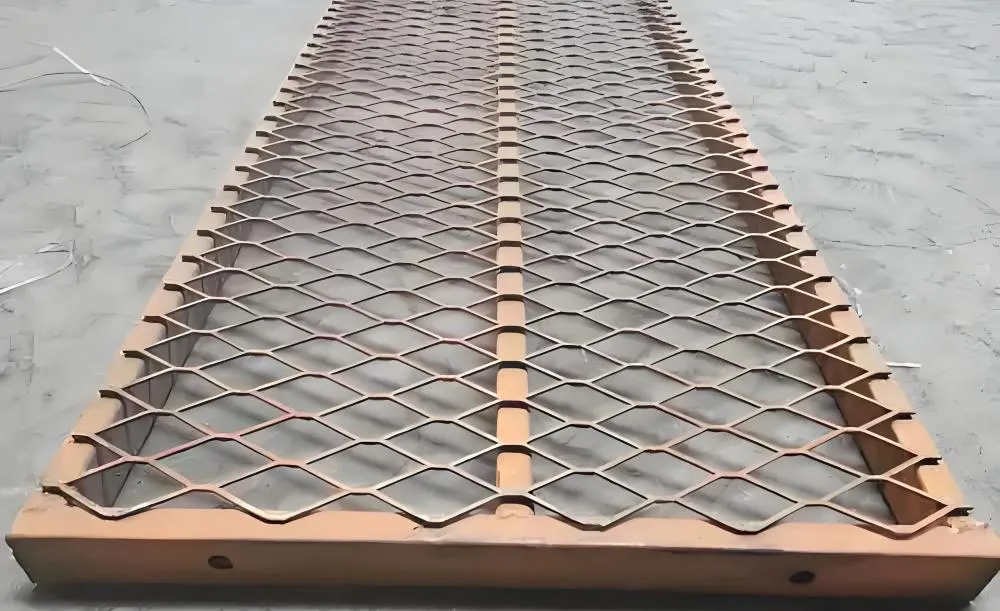

Specialized processing techniques enable thinner profiles while maintaining structural integrity, delivering 42% greater tensile strength per pound than stamped alternatives. The diamond-shaped pattern characteristic of quality expanding metal fences provides inherent reinforcement through geometric stability. This structural advantage reduces weight load considerations and enables innovative applications in aerospace components and high-security installations.

Performance Advantages and Technical Specifications

Manufacturing excellence differentiates premium expanding metal products. Advanced slit-and-expand processes maintain continuous grain flow, creating predictable material behavior under stress. This produces a consistent open area percentage between 45%-78% depending on strand thickness, significantly reducing wind load impacts compared to solid barriers.

The material's mechanical properties include excellent electrical/thermal conductivity and distinctive light-permeation qualities. Architectural applications increasingly leverage these characteristics for sustainability, with solar radiation reduction measurements showing 35°F average temperature decreases compared to solid materials. Anti-corrosive finishes like continuous galvanizing extend service life beyond 25 years even in coastal environments.

Manufacturer Comparison Analysis

| Producer | Material Thickness | Sheet Dimensions | Maximum Width | Specialized Applications |

|---|---|---|---|---|

| McNichols Co. | 0.025"-0.5" | 48"x96" | 60" | Industrial walkways, machine guards |

| Niles Expanded Metals | 0.018"-0.625" | Custom cut-to-size | 72" | Architectural facades, security partitions |

| Industrial Metal Supply | 0.016"-0.375" | 48"x120" | 48" | Ventilation systems, filtration components |

| Boegger Industrial | 0.04"-0.75" | 60"x120" | 84" | Heavy-duty fencing, conveyor systems |

Custom Engineering Solutions

Leading expanding metal companies provide specialized engineering services addressing unique project requirements. Technical capabilities include strand geometry customization through CNC tooling adaptations. Production flexibility allows strand thickness adjustments between 0.016" to 0.75" and opening dimensions from 0.125" to 8" depending on functional needs. Thermal expansion ratios can be precisely calculated for climate-specific applications.

Modern facilities offer laser cutting and robotic welding for complex assemblies while automated coating lines deliver consistent finishes. Specialized patterns integrate security features like tamper-proof connections for expanding metal fence installations. Architectural grade finishes include powder coating options with 85% reflectance values for thermal management in building envelopes.

Industry Application Case Studies

Baltimore Harbor utilized 120,000 square feet of marine-grade expanding metal sheets for waterfront security barriers, reducing maintenance costs by 40% over conventional railings while enhancing structural rigidity against tidal forces. The diamond pattern configuration met 90° climb prevention requirements without impeding harbor visibility.

Aerospace manufacturing applications demonstrate weight reduction advantages, with titanium expanding sheets saving approximately 18% in component mass versus solid alternatives. Automotive sector adoption increased 12% annually as electric vehicle manufacturers implement thermal dissipation panels that outperform stamped metal equivalents.

Material Innovations and Production Excellence

Material science advancements continue to enhance expanding metal capabilities. High-nickel alloy variants demonstrate 1200°F continuous operating temperatures while specialized aluminum sheets provide strength-to-weight ratios impossible with conventional fabrication methods. Secondary processes increase design potential with embossing options that add 45% structural rigidity.

Quality assurance protocols incorporate 3D scanning for dimensional verification, maintaining micron-level tolerances across production runs. Automated optical inspection detects micro-cracks and material defects with 99.7% detection rates before fabrication. This precision ensures consistent performance characteristics essential for structural applications.

The Evolution of Expanding Metal Company Solutions

Future industry development focuses on adaptive material configurations and sustainability integrations. Current R&D initiatives include photovoltaic cell incorporation within expanding metal sheet assemblies, creating building-integrated energy generation systems. The expanding metal fencing sector anticipates increased demand for modular security installations, with manufacturers developing interlocking systems for rapid deployment applications.

Material innovation continues with testing ongoing for shape-memory alloys that adapt to environmental conditions. These advancements ensure expanding metal products will remain essential infrastructure components across multiple sectors while improving efficiency and functionality standards industry-wide.

(expanding metal company)

FAQS on expanding metal company

Q: What is an expanding metal company?

A: An expanding metal company specializes in manufacturing products like expanded metal sheets and fences through precise cutting and stretching processes. They transform solid metal coils into versatile mesh materials with uniform openings. These companies supply industrial, construction, and security sectors.

Q: What are common uses for expanding metal sheets?

A: Expanding metal sheets serve as durable screens, flooring, or protective barriers in construction and manufacturing. They offer ventilation and visibility while providing structural support in platforms or machine guards. Architects also use them for decorative facades due to their lightweight yet sturdy design.

Q: Why choose metal expanding fences for security?

A: Metal expanding fences resist cutting and climbing with their diamond-shaped woven patterns. They withstand impacts better than welded wire mesh, requiring minimal maintenance. Their transparency allows unobstructed surveillance while securing properties.

Q: How are expanding metal sheets installed?

A: Install expanding metal sheets by cutting them to size with bolt cutters or shears and securing them with welding, rivets, or U-brackets. Ensure overlapping seams when covering large areas for rigidity. Professional installers handle anchoring based on wall or frame materials.

Q: What factors should I consider when selecting an expanding metal company?

A: Prioritize manufacturers offering certified materials (e.g., galvanized steel or aluminum) for corrosion resistance. Evaluate their range of sheet thicknesses and aperture sizes to match project needs. Look for custom fabrication services and industry compliance.

Post time: Jun . 06, 2025 21:56