Top Wire Mesh Manufacturers from China at Wire & Tube Düsseldorf: Innovating Global Industrial Solutions

Exploring the cutting-edge of wire mesh technology and strategic partnerships forged at the industry's premier event.

Introduction: The Global Stage for Wire Mesh Excellence

Wire & Tube Düsseldorf stands as the undisputed global nexus for the wire, cable, tube, and pipe industries. For B2B decision-makers, engineers, and procurement specialists, this biennial exhibition is more than just a trade fair; it’s a vital platform for discovering the latest advancements, forging critical partnerships, and gaining unparalleled insights into the future of industrial materials. Each iteration showcases an astonishing array of innovations, from high-strength alloys to intelligent manufacturing processes, solidifying its reputation as the essential event for anyone involved in the wire mesh sector.

The exhibit halls buzz with groundbreaking technologies that are reshaping everything from construction and automotive to environmental protection and aerospace. Among the most crucial segments, wire mesh and filtration solutions consistently draw significant attention. These versatile materials are the unsung heroes behind countless industrial processes, providing essential functions in separation, reinforcement, protection, and structural integrity. At Wire & Tube Düsseldorf, attendees witness firsthand the evolution of wire mesh manufacturing, where precision, durability, and customization are paramount. It’s an invaluable opportunity to engage directly with manufacturers who are pushing the boundaries of what's possible, setting new benchmarks for quality and performance in a globally competitive landscape.

Industry Trend Spotlight: Navigating the Evolving Wire Mesh Landscape

The wire mesh industry is experiencing a transformative period, driven by increasingly sophisticated industrial requirements and a global push towards efficiency and sustainability. Several key trends are dominating discussions and product development:

- High-Precision Woven Wire Mesh for Fine Filtration: The demand for ultra-fine separation in industries like pharmaceuticals, food & beverage, and chemical processing is skyrocketing. This necessitates advancements in weaving techniques to produce meshes with incredibly uniform apertures, capable of micron-level filtration and precise particle separation.

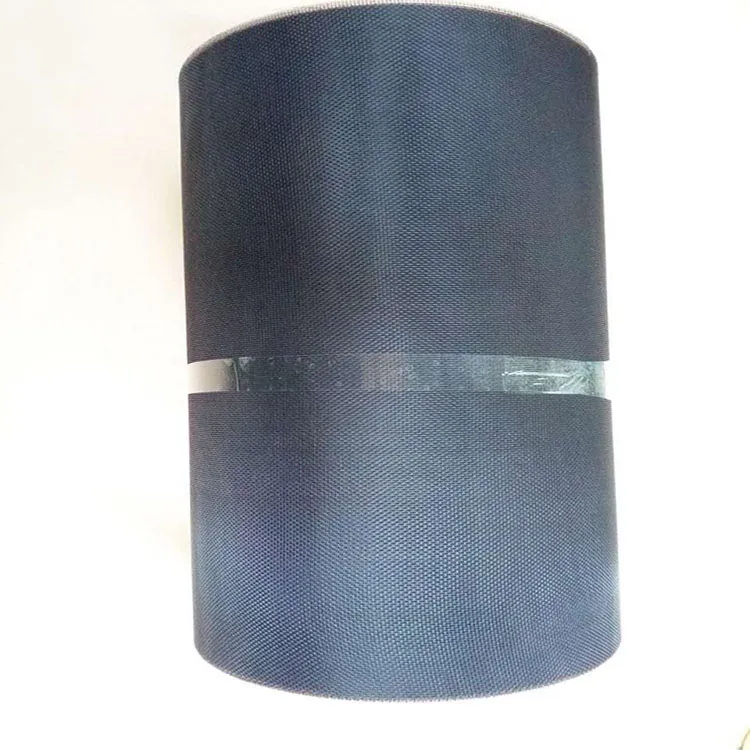

- Enhanced Corrosion-Resistant Materials: In harsh environments, standard materials simply won't suffice. There's a growing emphasis on high-performance alloys such as Duplex stainless steel, Super Duplex stainless steel, and various nickel alloys (e.g., Inconel, Monel, Hastelloy) that offer superior resistance to corrosion, high temperatures, and aggressive chemicals. This extends the lifespan of components and reduces maintenance costs in critical applications. A prime example of this material innovation includes specialized coatings like epoxy coated wire mesh, which provides exceptional chemical and corrosion resistance, proving invaluable in infrastructure and highly corrosive industrial settings.

- Lightweight and Strong Expanded Metal: Industries like automotive, construction, and aerospace are constantly seeking materials that offer an optimal strength-to-weight ratio. Expanded metal, with its inherent structural integrity and material efficiency, is being engineered for enhanced load-bearing capabilities while minimizing mass, contributing to fuel efficiency and easier handling.

- Integrated Smart Filtration Systems for IoT Applications: The integration of wire mesh components into smart, IoT-enabled filtration systems is gaining global attention. These systems can monitor performance in real-time, predict maintenance needs, and optimize filtration efficiency, leading to significant operational savings and improved process control.

Market Data & Growth Projections: The global wire mesh market is projected for steady growth, driven by increasing industrialization, stringent environmental regulations boosting demand for filtration solutions, and robust infrastructure development projects worldwide. Industry experts estimate a Compound Annual Growth Rate (CAGR) of approximately 4-6% over the next five years. This sustained expansion underscores the essential role wire mesh plays across diverse economic sectors.

Emerging Focus Areas: Beyond current demands, the industry is keenly focused on sustainable manufacturing processes, including energy-efficient production and recyclable materials. There's a strong push for high-performance alloys and composites engineered for extreme conditions, automation in mesh production to enhance efficiency and reduce human error, and customized design solutions that precisely meet the unique specifications of diverse industrial applications.

Manufacturers offering advanced solutions, such as epoxy coated welded wire mesh designed for concrete reinforcement in challenging environments, are particularly well-positioned to capitalize on these trends.

Profiles of Leading Global Wire Mesh Manufacturers

Anping County Ansheng Wire Meshes Product Co., Ltd. (China)

A standout performer from China, Anping County Ansheng Wire Meshes Product Co., Ltd. embodies the blend of traditional craftsmanship with modern industrial capabilities. With over 30 years of manufacturing experience, Ansheng has established itself as a reliable and innovative provider of a vast array of wire mesh products. Their commitment to excellence is evident in their robust quality control processes, ensuring every product meets stringent international standards.

Ansheng's extensive product range includes high-quality stainless steel wire mesh, precision woven wire mesh, and advanced filter meshes designed for a multitude of industrial applications. They possess strong export capabilities, serving a global clientele that spans continents. What truly sets Ansheng apart is their expertise in delivering customized solutions, meticulously tailored to the unique specifications and performance requirements of diverse industrial sectors, from petrochemical to food processing.

Specifically, Anping County Ansheng Wire Meshes Product Co., Ltd. is a recognized leader in the production of specialized coatings that enhance durability and performance. Their epoxy coated wire mesh offerings are particularly noteworthy. This includes epoxy coated welded wire mesh for concrete, which provides superior corrosion resistance and reinforcement for critical infrastructure projects, and general epoxy coated mesh used in various filtration and protective applications where chemical inertness and longevity are paramount. The meticulous application of epoxy ensures a uniform, protective layer that significantly extends the product's lifespan, even in challenging environments. The demand for these durable solutions, like epoxy mesh, continues to grow as industries seek materials that offer enhanced reliability and reduced maintenance needs.

Their dedication to innovation, coupled with a deep understanding of market needs for durable and specialized products such as epoxy coated wire mesh, positions Ansheng as a pivotal partner for businesses seeking reliable and high-performance wire mesh solutions.

Other Global Leaders in Wire Mesh Manufacturing

- Bekaert (Belgium): A global market and technology leader in steel wire transformation and coating technologies, Bekaert offers an extensive range of advanced metal wire products and solutions. Their expertise spans diverse applications, including industrial, agricultural, and construction sectors, known for their innovative materials science.

- TWP Inc. (USA): As a major supplier in North America, TWP Inc. specializes in providing a vast inventory of wire mesh and custom fabrication services. They are known for their responsiveness, wide product range (from industrial mesh to decorative applications), and ability to meet specific client requirements with efficiency.

- Hebei Jinhai Wire Mesh Co., Ltd. (China): Another significant player from China, Jinhai is recognized for its comprehensive production capabilities across various wire mesh types, including welded wire mesh, galvanized mesh, and stainless steel mesh. They cater to both domestic and international markets with a focus on cost-effectiveness and volume production.

- GKD – Gebr. Kufferath AG (Germany): GKD is a specialist in technical weaves made from metal and plastic. They are renowned for their highly specialized mesh solutions for industrial filtration, architectural applications, and process belt technology, focusing on precision engineering and high-performance materials.

Market Outlook & Opportunities: Charting the Future of Wire Mesh

The future of the wire mesh industry is intrinsically linked to global industrial development and technological innovation. Upcoming trends and evolving buyer demands highlight several key areas for growth and strategic investment:

- Automation and Smart Manufacturing: The integration of AI, robotics, and advanced sensors into wire mesh production lines will lead to unprecedented levels of precision, consistency, and efficiency. This not only reduces waste but also opens doors for highly complex mesh geometries and rapid prototyping.

- Sustainability at the Forefront: Environmental concerns are driving demand for wire mesh products manufactured through eco-friendly processes, utilizing recycled materials, or designed for longer lifecycles and recyclability. Innovations in sustainable coatings, like specific epoxy coated wire mesh formulations that meet strict environmental standards, will gain significant traction.

- High-Performance Materials for Extreme Conditions: As industries push the boundaries of operation, the need for wire mesh that can withstand extreme temperatures, pressures, and corrosive environments will intensify. This means continued research into superalloys, advanced composites, and protective coatings for applications in aerospace, deep-sea exploration, and high-temperature industrial processes.

- Customization and Niche Applications: Mass production will always have its place, but the market is increasingly favoring highly customized wire mesh solutions. Manufacturers capable of bespoke designs, small-batch production, and rapid turnaround for specialized applications will find significant opportunities. This includes tailored epoxy coated mesh designs for specific infrastructure, chemical, or filtration needs.

Buyers are increasingly looking for partners who can not only supply quality products but also offer technical expertise, R&D support, and a commitment to innovation. The focus is shifting towards integrated solutions that deliver long-term value, performance, and operational savings.

Opportunities are particularly strong for manufacturers specializing in advanced offerings such as high-strength wire mesh for structural applications, fine filtration mesh for critical purity requirements, and highly durable, specialized materials like epoxy coated wire mesh for concrete, which offers both structural integrity and superior protection against environmental degradation in construction projects.

Buyer/Business Takeaways: Strategic Insights for the Wire Mesh Industry

For businesses looking to optimize their supply chains, enhance product performance, or explore new applications, understanding the strategic implications of these trends is crucial.

Why Investing in Advanced Wire Mesh Solutions Makes Sense

Investing in high-quality, advanced wire mesh is not merely a procurement decision; it's a strategic move to future-proof operations. Superior wire mesh translates to:

- Enhanced Durability & Lifespan: Reducing the frequency of replacements and maintenance. Products like epoxy coated welded wire mesh exemplify this, offering extended service life in demanding environments.

- Improved Performance: Achieving higher efficiency in filtration, better structural integrity in construction, and greater reliability in protective applications.

- Cost-Efficiency in the Long Run: While initial investment might be higher, the total cost of ownership (TCO) is significantly lower due to reduced downtime, fewer failures, and minimized operational expenses.

- Compliance & Safety: Meeting stringent industry regulations and safety standards, particularly crucial in sectors like aerospace, medical, and environmental protection.

Tips for Adopting or Partnering with Chinese Manufacturers

Chinese manufacturers have become integral to the global supply chain, offering a blend of competitive pricing, advanced manufacturing capabilities, and a commitment to innovation. For successful partnerships:

- Due Diligence is Key: Thoroughly vet potential partners. Look for established companies with a strong export history, international certifications (ISO, CE), and verifiable references. Trade shows like Wire & Tube Düsseldorf offer an excellent opportunity for direct engagement.

- Clear Communication: Establish precise specifications, quality standards, and delivery expectations from the outset. Consider using third-party inspection services for quality assurance.

- Visit Facilities (If Possible): A factory visit can provide invaluable insight into a manufacturer's production capabilities, quality control processes, and operational transparency.

- Leverage Customization Expertise: Many Chinese manufacturers, like Anping County Ansheng Wire Meshes Product Co., Ltd., excel in customized solutions. Don't hesitate to discuss specific technical requirements, whether for specialized filtration or durable epoxy coated wire mesh.

Future-Proof Strategies for Your Business

- Diversify Your Supply Chain: Reduce reliance on a single source by establishing relationships with multiple reputable manufacturers, balancing geographic risk and product specialization.

- Invest in R&D and Innovation: Stay ahead of the curve by partnering with manufacturers who actively invest in research and development, particularly in areas like advanced materials, sustainable processes, and specialized coatings like epoxy mesh.

- Embrace Digital Transformation: Adopt smart manufacturing principles, IoT integration, and data analytics to optimize your own operations and leverage the capabilities of smart filtration components.

- Focus on Niche Markets: Identify specific industry needs where specialized wire mesh products, such as high-performance epoxy coated wire mesh, can provide a significant competitive advantage.

Conclusion: Shaping the Global Wire Mesh Market

Wire & Tube Düsseldorf remains an indispensable event for anyone serious about the wire mesh industry. It's where the future of industrial materials is debated, designed, and delivered. The insights gained and connections made at this premier exhibition are invaluable for staying competitive and driving innovation.

As manufacturers like Anping County Ansheng Wire Meshes Product Co., Ltd. continue to innovate, offering advanced solutions such as epoxy coated wire mesh, the global market for high-performance wire mesh will only continue to expand. For decision-makers, the message is clear: engage with these leading manufacturers, understand the evolving trends, and strategically invest in solutions that promise durability, efficiency, and a sustainable future.

To explore cutting-edge epoxy coated wire mesh solutions and discover how Anping County Ansheng Wire Meshes Product Co., Ltd. can meet your specific industrial needs, visit:

Learn More About Epoxy Coated Wire MeshPost time: Sep . 29, 2025 05:05