Epoxy Coated Wire Mesh for Concrete: What Pros Are Actually Using on Site

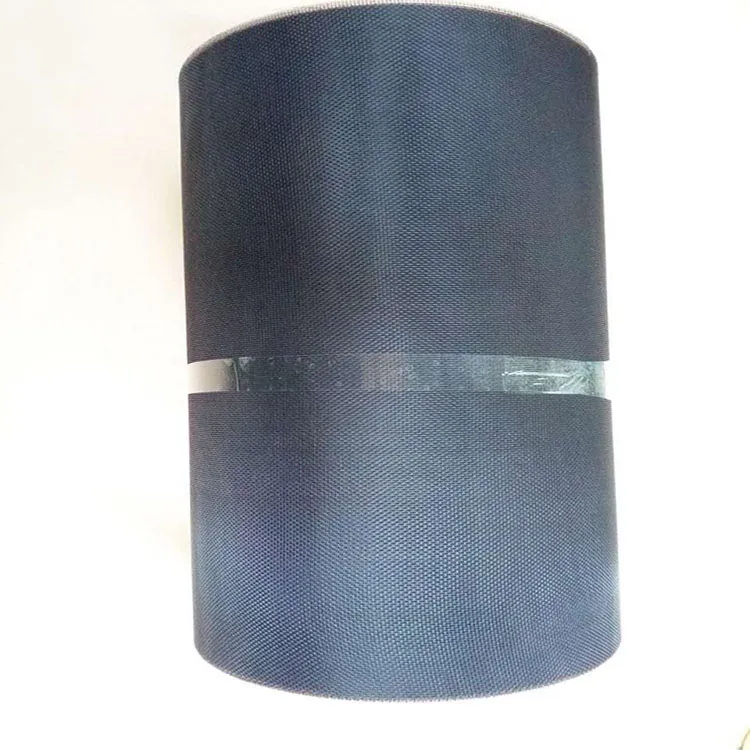

On real jobs—bridge decks, precast panels, even parking structures—the quiet workhorse isn’t always the rebar. It’s the supporting mesh. Lately I’ve been hearing from foremen and QC techs about epoxy coated wire mesh for concrete that holds up against salt, thaw cycles, and site handling better than expected. To be honest, the buzz makes sense: you combine welded wire reinforcement with a controlled epoxy film, and you get a more forgiving, corrosion-resistant layer that bonds well with cement paste.

Quick product snapshot (field-ready)

Product: Epoxy Coated Wire Mesh by Ansheng Wire Mesh (Origin: No.346 Xinying East Street, Anping County, Hebei, China). Many customers say the uniform green coating is “tougher than it looks,” especially around tie points.

| Parameter | Typical value (≈ / real-world may vary) |

|---|---|

| Base wire | Low-carbon steel wire, welded; optional galvanized pre-coat |

| Wire diameter | Ø 0.6–2.5 mm (custom larger on request) |

| Aperture / mesh count | 1.5–6 mm aperture or 8–30 mesh |

| Epoxy coating thickness | 60–120 μm (checked per ASTM D7091) |

| Tensile strength | ≥ 500 MPa (wire), weld shear verified |

| Roll width / length | 0.5–1.5 m width; 30–100 m length |

| Standards it aligns with | ASTM A884/A884M; salt spray per ASTM B117 |

How it’s made (short, honest version)

Materials: low-carbon steel wire → welded into mesh → surface prep (alkali degrease, rinse, shot-blast or acid activation) → epoxy powder electrostatic spray → thermal cure. Methods are fairly standard, but the consistency of pretreatment is where good vendors separate themselves.

QC and testing: coating thickness (ASTM D7091), adhesion (ASTM D3359 or D4541), bend test (per ASTM A884 guidance), salt spray 500–1500 h (ASTM B117). Holiday checks on high-sensitivity jobs. Service life? In typical de-icing salt exposure, field engineers estimate 25–50 years assuming correct cover and crack control—ACI 318 practices still apply.

Where it’s used (and why it sticks)

- Concrete: bridge decks, precast facades, parking slabs, shotcrete linings, culverts. epoxy coated wire mesh for concrete reduces early corrosion initiation and mitigates staining from rust bleed.

- Industrial: as filter support layers in hydraulic/air filtration (holds media shape under pressure spikes).

- Civil/safety: high-end apartment and office safety screens—clean look, steady rigidity.

Big advantages: better corrosion resistance than bare mesh, improved bond with cement paste, fewer callbacks from edge rust after cutting (touch-up epoxy recommended), and—surprisingly—faster placement because the coating reduces snagging on gloves and ties.

Vendor landscape (my candid take)

| Vendor | Customization | Lead time | Certs / reports | Notes |

|---|---|---|---|---|

| Ansheng Wire Mesh | Aperture, width, color, coating μm | ≈ 2–4 weeks | ISO 9001; ASTM B117, D7091 data | Strong in filter-grade support mesh and concrete |

| Local fabricator | Limited mesh range | 1–2 weeks | Basic CoC, sometimes no salt-spray | Fast, but variable coating quality |

| Generic importer | Mixed; MOQ applies | 4–8 weeks | Specs on request | Price-driven, check weld shear tests |

Mini case notes

- Coastal parking deck: epoxy coated wire mesh for concrete with 100 μm film, B117 > 1000 h; zero red rust at scribe after approved patching on cuts.

- Precast facade plant: faster demold by ~6%, fewer mesh print-through marks—coating smoothed contact with form liners.

- Hydraulic filter OEM: switch to epoxy mesh support reduced media collapse incidents; warranty claims down 8% year-on-year.

Spec tips before you buy

Call out: wire diameter, aperture, epoxy thickness, salt-spray hours, adhesion method, weld shear, and touch-up kit compliance. For structural elements, align with ASTM A884/A884M; for durability, don’t skip ACI cover requirements. And yes, get the test sheets—real data beats brochure talk.

Citations

- ASTM A884/A884M — Standard Specification for Epoxy-Coated Steel Wire and Welded Wire Reinforcement for Concrete.

- ASTM B117 — Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ASTM D7091 — Standard Practice for Measurement of Dry Film Thickness of Nonmagnetic Coatings.

- ASTM D3359 / D4541 — Adhesion testing methods for coatings.

- ACI 318 — Building Code Requirements for Structural Concrete (cover and durability provisions).

Post time: Oct . 18, 2025 16:45