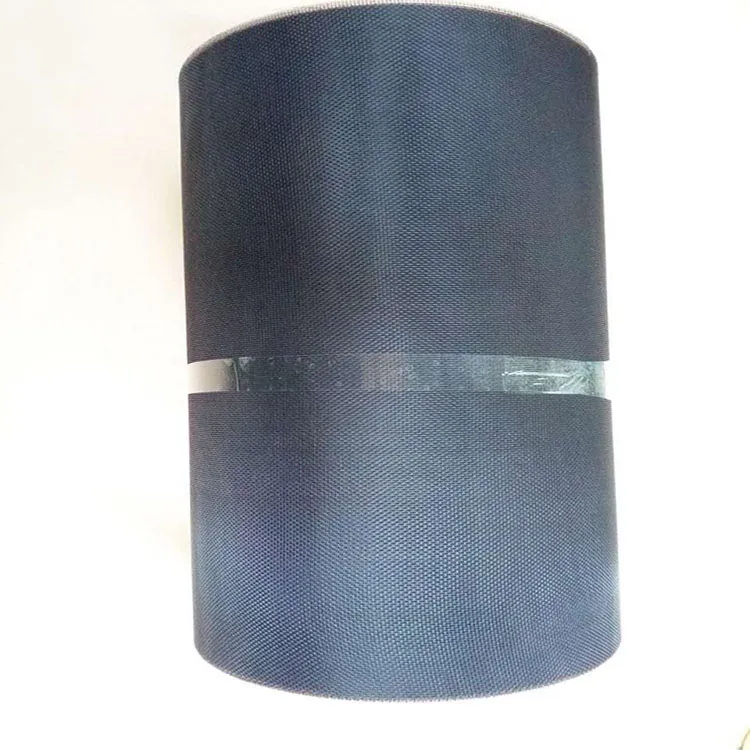

Epoxy Coated Wire Mesh: Durable Solution for Concrete Reinforcement and Industrial Applications

At Anping County Ansheng Wire Meshes Product Co., Ltd., we specialize in providing high-quality epoxy coated wire mesh designed to meet the demands of modern construction and industrial applications. Our products are engineered with advanced technology to ensure superior performance, durability, and resistance to corrosion, making them ideal for a wide range of uses. Whether you're reinforcing concrete structures or seeking a reliable material for industrial purposes, our epoxy coated welded wire mesh offers a long-term solution that delivers exceptional value.

Product Overview and Core Advantages

Our epoxy coated wire mesh is a specialized material that combines the strength of steel wire with a protective epoxy coating. This coating not only enhances the mesh's resistance to rust and corrosion but also improves its durability in harsh environments. The epoxy coated mesh is commonly used in epoxy coated wire mesh for concrete applications, where it provides structural reinforcement and ensures long-term stability. Its versatility allows it to be applied in both residential and commercial projects, making it a preferred choice for construction professionals.

Key Features and Technical Specifications

- Durability: The epoxy coating provides exceptional resistance to weathering, chemicals, and mechanical stress, ensuring a longer lifespan.

- Corrosion Resistance: The coating prevents rust and degradation, making it suitable for outdoor and high-moisture environments.

- Strength: The steel wire base offers high tensile strength, ideal for reinforcing concrete structures and industrial applications.

- Customization: Available in various mesh sizes, wire diameters, and coatings to meet specific project requirements.

- Environmental Compliance: The epoxy coating is non-toxic and environmentally friendly, ensuring safe use in sensitive areas.

Market Demand and Industry Pain Points

The construction and industrial sectors face significant challenges in finding materials that balance strength, durability, and cost-effectiveness. Traditional steel meshes are prone to corrosion, leading to structural weaknesses and costly repairs. Additionally, the demand for sustainable and eco-friendly solutions has increased, prompting industries to seek alternatives that meet modern environmental standards.

Our epoxy coated welded wire mesh addresses these challenges by offering a material that combines the strength of steel with the protection of an epoxy coating. This innovation not only extends the product's lifespan but also reduces maintenance costs and environmental impact. Whether used in concrete reinforcement, fencing, or industrial machinery, our epoxy coated wire mesh provides a reliable and efficient solution for today's industries.

Company Background and Technological Expertise

As a leading manufacturer in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a trusted provider of high-performance epoxy coated wire mesh. With decades of experience, we have developed advanced production techniques and quality control systems to ensure that every product meets international standards. Our commitment to innovation and customer satisfaction has earned us a strong reputation among clients worldwide.

Our research and development team continuously improves our epoxy coated mesh technology, ensuring that it adapts to the evolving needs of the market. By integrating cutting-edge materials and manufacturing processes, we deliver products that exceed industry expectations in terms of performance and reliability.

Product Performance and Customer Testimonials

Customers who have used our epoxy coated wire mesh report significant improvements in project outcomes. For instance, a construction company in the United States noted that the use of epoxy coated welded wire mesh in their concrete projects reduced maintenance costs by over 40% compared to traditional steel mesh. Another client in the industrial sector highlighted the mesh's ability to withstand harsh conditions without compromising structural integrity.

One of our satisfied clients shared, "The epoxy coated wire mesh we purchased from Anping County Ansheng has significantly improved the durability of our infrastructure. We highly recommend their products to others in the industry." These testimonials reflect the trust and satisfaction that our clients place in our solutions.

Usage Guidelines and Customization Options

Our epoxy coated wire mesh is designed for easy installation and compatibility with various construction techniques. For epoxy coated wire mesh for concrete applications, it is recommended to follow standard reinforcement guidelines, ensuring proper placement and anchoring. The mesh can also be customized to fit specific project dimensions, allowing for greater flexibility in design and implementation.

For industrial applications, our team offers tailored solutions to meet unique operational requirements. Whether you need a specific mesh size, coating thickness, or additional features, we can provide a customized product that aligns with your needs.

Safety and Compliance

At Anping County Ansheng Wire Meshes Product Co., Ltd., we prioritize the safety and well-being of our customers. Our epoxy coated wire mesh is manufactured in compliance with international safety standards, ensuring that it is non-toxic and environmentally friendly. The epoxy coating is free from harmful substances, making it suitable for use in residential, commercial, and industrial settings.

Furthermore, our products are tested to meet rigorous quality and performance criteria, guaranteeing that they deliver consistent results in any application. This commitment to safety and compliance is a testament to our dedication to excellence.

Packaging and Logistics

Our epoxy coated wire mesh is packaged to ensure safe transportation and storage. For bulk orders, we offer customized packaging solutions that protect the product during transit while minimizing costs. We also provide efficient logistics support, ensuring timely delivery to clients across the globe.

Customer Support and After-Sales Service

We are committed to providing exceptional customer support throughout the entire product lifecycle. Our team of experts is available to offer technical consultations, installation guidance, and troubleshooting assistance. For any inquiries or issues, we guarantee prompt and professional service to ensure your satisfaction.

Additionally, we offer product customization and on-site support for large-scale projects. Our goal is to ensure that every client receives the highest level of service and value from our epoxy coated wire mesh.

Contact Us for More Information

For more details about our epoxy coated wire mesh and other products, visit our company website or contact us directly. Our dedicated team is here to help you find the right solution for your needs.

FAQ: Frequently Asked Questions

What are the primary applications of epoxy coated wire mesh?

The epoxy coated wire mesh is widely used in concrete reinforcement, industrial machinery, fencing, and architectural applications. Its durability and corrosion resistance make it ideal for both indoor and outdoor use.

How does the epoxy coating enhance the product's performance?

The epoxy coating acts as a protective barrier, preventing rust and degradation caused by moisture, chemicals, and UV exposure. This significantly extends the product's lifespan and maintains its structural integrity.

Can the mesh be customized for specific projects?

Yes, we offer customization options for mesh size, wire diameter, and coating thickness to meet your unique requirements. Our team works closely with clients to develop tailored solutions.

What is the typical delivery time for orders?

Delivery times vary depending on the order size and destination. We ensure efficient logistics to minimize delays and provide timely delivery to our clients.

Is the epoxy coated wire mesh environmentally friendly?

Yes, the epoxy coating is non-toxic and environmentally compliant. It meets international standards for safety and sustainability, making it a responsible choice for modern industries.

Conclusion

Invest in high-quality epoxy coated wire mesh from Anping County Ansheng Wire Meshes Product Co., Ltd. to enhance the durability and efficiency of your projects. With our advanced technology, reliable performance, and exceptional customer service, we are committed to delivering solutions that meet your needs and exceed your expectations.

Post time: Jul . 20, 2025 22:01