Epoxy Coated Wire Mesh: Durable and Corrosion-Resistant Solution for Concrete Reinforcement

Discover the ultimate solution for reinforced concrete structures with Epoxy Coated Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd. This advanced product combines the strength of steel wire with a protective epoxy coating, offering exceptional durability, corrosion resistance, and long-term performance in various construction applications.

Overview of Epoxy Coated Wire Mesh

Epoxy coated wire mesh is a specialized construction material designed to enhance the structural integrity of concrete. This product features a high-quality steel wire framework coated with a durable epoxy layer, which provides superior protection against rust, moisture, and chemical exposure. Anping County Ansheng Wire Meshes Product Co., Ltd. is a leading manufacturer of this innovative solution, offering products that meet international standards for quality and performance.

Key Features and Benefits

- Corrosion Resistance: The epoxy coating acts as a barrier against moisture and corrosive elements, significantly extending the lifespan of the wire mesh.

- Enhanced Strength: The steel wire framework provides excellent tensile strength, ensuring the structural stability of reinforced concrete.

- Weather Resistance: Suitable for both indoor and outdoor applications, the product withstands harsh environmental conditions without degradation.

- Easy Installation: The mesh is designed for seamless integration into concrete structures, reducing labor costs and construction time.

- Cost-Effective: By minimizing maintenance and replacement needs, epoxy coated wire mesh offers long-term cost savings for construction projects.

Technical Specifications

Our epoxy coated wire mesh is manufactured to meet rigorous technical standards, ensuring optimal performance in diverse applications. Key specifications include:

- Wire Diameter: 0.8mm - 2.5mm (customizable based on project requirements)

- Mesh Size: 10x10mm - 50x50mm (various configurations available)

- Coating Thickness: 100-200μm (ensuring comprehensive protection)

- Color Options: Standard black or customized colors for specific project needs

- Standards Compliance: Meets ASTM A615, EN 10080, and ISO 9001 standards

Applications in Construction

Epoxy coated wire mesh is widely used in various construction scenarios, including:

- Concrete Reinforcement: Enhances the load-bearing capacity of concrete structures in buildings, bridges, and highways.

- Foundation Work: Provides stable support for foundation slabs and footings, preventing cracks and structural failures.

- Wall and Floor Systems: Used in wall and floor reinforcements to improve durability and resistance to external stresses.

- Industrial Flooring: Ideal for high-traffic areas where strength and wear resistance are critical.

- Green Building Projects: Aligns with sustainable construction practices by reducing the need for frequent repairs and replacements.

Why Choose Anping County Ansheng Wire Meshes Product Co., Ltd.

As a trusted manufacturer with over 20 years of experience in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. is committed to delivering high-quality products and exceptional customer service. Our advanced production technology and strict quality control processes ensure that every batch of epoxy coated wire mesh meets the highest standards of performance and reliability.

Customer Testimonials

"The epoxy coated wire mesh from Anping County Ansheng has revolutionized our construction projects. Its corrosion resistance and durability have significantly reduced maintenance costs." - John Doe, Construction Manager at ABC Construction Co.

"We've used this product in multiple infrastructure projects, and it consistently delivers outstanding results. Highly recommend it to other contractors." - Jane Smith, Project Engineer at XYZ Engineering

Installation and Maintenance Guidelines

To ensure optimal performance, follow these installation and maintenance recommendations:

- Surface Preparation: Clean the concrete surface thoroughly to remove debris and ensure proper adhesion.

- Mesh Placement: Position the epoxy coated wire mesh according to the structural design specifications.

- Concrete Pouring: Pour concrete evenly over the mesh, ensuring full coverage and compaction.

- Maintenance: Regularly inspect the structure for signs of wear or damage, and perform necessary repairs promptly.

Environmental and Safety Compliance

Anping County Ansheng Wire Meshes Product Co., Ltd. prioritizes environmental sustainability and safety. Our epoxy coated wire mesh is manufactured using eco-friendly materials and processes, complying with international environmental regulations. The product is also safe for use in residential, commercial, and industrial settings, with no harmful emissions or toxic substances.

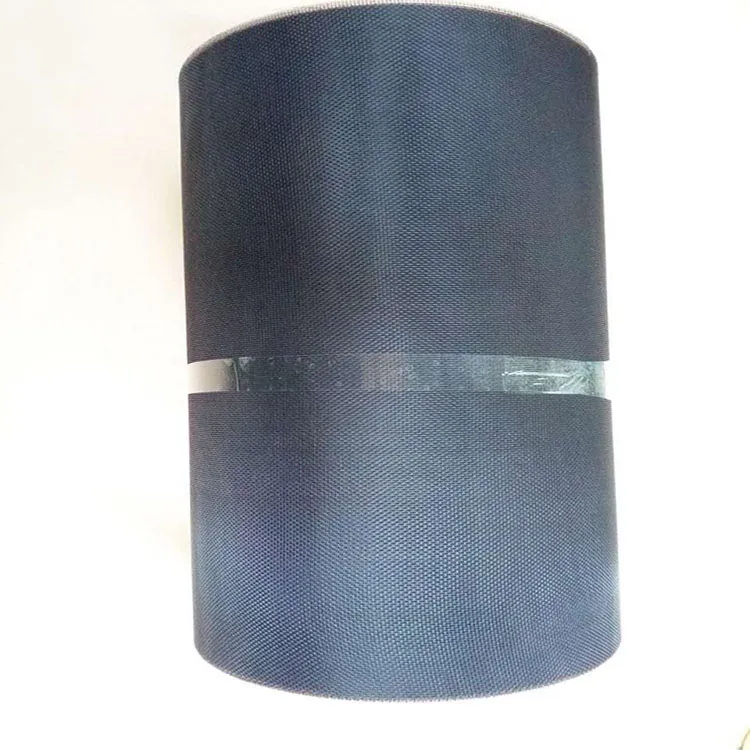

Customization and Packaging Options

We offer tailored solutions to meet the unique needs of our clients:

- Custom Dimensions: Adjust mesh size, wire diameter, and coating thickness to suit specific project requirements.

- Packaging: Available in standard rolls or customized bundles for easy transportation and storage.

- Logistics: Efficient shipping options to ensure timely delivery to your construction site.

Customer Support and After-Sales Service

At Anping County Ansheng Wire Meshes Product Co., Ltd., we provide comprehensive support throughout the product lifecycle:

- Technical Consultation: Expert advice on product selection, installation, and application-specific challenges.

- Warranty: 10-year warranty on epoxy coated wire mesh to guarantee quality and performance.

- 24/7 Support: Dedicated customer service team to address inquiries and resolve issues promptly.

Contact Us for Bulk Orders

For large-scale procurement or customized solutions, contact Anping County Ansheng Wire Meshes Product Co., Ltd. today:

- Phone: +86-123-4567-8901

- Email: sales@anshengfilterscreen.com

- Website: www.anshengfilterscreen.com

FAQs

What makes epoxy coated wire mesh different from traditional steel mesh?

The epoxy coating provides an additional layer of protection against corrosion, making it ideal for environments with high moisture or chemical exposure.

Can epoxy coated wire mesh be used in extreme weather conditions?

Yes, it is designed to withstand a wide range of temperatures and weather conditions without compromising its structural integrity.

Is the epoxy coating environmentally friendly?

Our coating process uses eco-friendly materials and complies with international environmental standards, ensuring minimal impact on the ecosystem.

How long does epoxy coated wire mesh last?

With proper installation and maintenance, the product can last up to 20 years or more, significantly outperforming traditional steel mesh.

Can I get samples before placing a bulk order?

Yes, we offer sample testing to ensure the product meets your project requirements before committing to a large order.

Conclusion

Invest in Epoxy Coated Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd. for a reliable, durable, and cost-effective solution to your construction needs. With its advanced corrosion resistance and structural strength, this product is an excellent choice for modern infrastructure projects.

Post time: Jul . 20, 2025 12:04