Epoxy Coated Wire Mesh: Durable and Corrosion-Resistant Solution for Concrete Reinforcement

At Anping County Ansheng Wire Meshes Product Co., Ltd., we specialize in providing high-quality epoxy coated wire mesh solutions for industrial and construction applications. Our epoxy coated welded wire mesh is engineered to deliver exceptional durability, corrosion resistance, and structural integrity, making it an ideal choice for concrete reinforcement and other demanding environments.

What is Epoxy Coated Wire Mesh?

Epoxy coated wire mesh is a type of steel wire mesh coated with a protective epoxy layer to enhance its resistance to corrosion, chemicals, and environmental degradation. This coating is particularly beneficial in applications where the mesh is exposed to moisture, humidity, or aggressive chemicals, such as in concrete structures, industrial flooring, and outdoor construction projects.

The epoxy mesh is manufactured using high-quality carbon steel wires, which are then coated with a durable epoxy resin. This process not only prevents rust and oxidation but also improves the mesh's tensile strength and overall lifespan. The result is a product that combines the structural benefits of steel mesh with the protective properties of an epoxy coating.

Key Features and Benefits

1. Corrosion Resistance

The epoxy coating acts as a barrier against moisture and chemicals, significantly reducing the risk of rust and degradation. This makes our epoxy coated wire mesh for concrete ideal for use in marine environments, industrial facilities, and other high-moisture areas.

2. Enhanced Durability

The combination of high-strength steel wires and the epoxy coating ensures that our mesh can withstand heavy loads, mechanical stress, and harsh environmental conditions. This durability translates to long-term cost savings for our customers.

3. Versatile Applications

Our epoxy coated welded wire mesh is suitable for a wide range of applications, including:

- Concrete reinforcement in construction projects

- Industrial flooring and walkways

- Bridge and highway construction

- Garage floors and parking structures

- Chemical and wastewater treatment facilities

Technical Specifications

Our epoxy coated wire mesh is available in a variety of configurations to meet different project requirements. Key technical specifications include:

- Wire Diameter: 1.0mm to 6.0mm

- Mesh Size: 10x10mm to 50x50mm

- Coating Thickness: 100-200 microns

- Coating Color: Available in standard colors (e.g., green, red, yellow) or custom options

- Load Capacity: Up to 500 kg/m² depending on mesh size and wire diameter

These specifications ensure that our products can be tailored to specific project needs, whether for residential, commercial, or industrial use.

Market Demand and Industry Trends

The construction and industrial sectors are increasingly seeking materials that offer both performance and longevity. Traditional steel mesh is prone to corrosion, which can lead to structural weaknesses and costly repairs. Our epoxy coated wire mesh addresses these challenges by providing a corrosion-resistant alternative that maintains its structural integrity over time.

With the growing emphasis on sustainable construction practices, our products also align with environmental standards. The epoxy coating reduces the need for frequent replacements, minimizing waste and resource consumption. This makes our epoxy coated mesh a preferred choice for eco-conscious builders and engineers.

Why Choose Anping County Ansheng Wire Meshes Product Co., Ltd.?

As a leading manufacturer in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. has built a reputation for quality, innovation, and customer satisfaction. Our commitment to excellence is reflected in the following aspects:

- Advanced Manufacturing Technology: We utilize state-of-the-art production equipment to ensure precision and consistency in every product.

- Comprehensive Quality Control: Our rigorous testing processes guarantee that all products meet international standards for performance and safety.

- Customization Options: We offer tailored solutions to meet specific project requirements, including custom mesh sizes, coatings, and configurations.

- Global Distribution Network: Our products are exported to over 50 countries, ensuring reliable delivery and support worldwide.

Customer Testimonials

Our epoxy coated wire mesh has received positive feedback from clients across various industries. Here are some of their testimonials:

"The epoxy coated welded wire mesh we purchased from Anping County Ansheng has significantly improved the durability of our concrete structures. The corrosion resistance is outstanding, and we've seen a noticeable reduction in maintenance costs."

- John D., Construction Manager, USA

"As a manufacturer of industrial flooring, we rely on high-quality materials to ensure the safety and longevity of our products. Anping County Ansheng's epoxy coated wire mesh has exceeded our expectations, providing excellent strength and resistance to harsh environments."

- Maria L., Plant Director, Germany

How to Use Epoxy Coated Wire Mesh

Proper installation is crucial to maximizing the performance of epoxy coated wire mesh. Here are some guidelines for effective use:

- Surface Preparation: Ensure the substrate is clean, dry, and free of debris before installation.

- Mesh Placement: Lay the mesh in the desired location, ensuring proper alignment and spacing according to design specifications.

- Fixing Methods: Use appropriate fasteners or welding techniques to secure the mesh in place.

- Concrete Pouring: Pour concrete over the mesh, ensuring full coverage and proper compaction.

For specific applications, our technical team can provide detailed recommendations and support to ensure optimal results.

Customization and Solutions

We understand that each project has unique requirements. That's why we offer epoxy coated wire mesh solutions tailored to your specific needs. Whether you require a particular mesh size, coating color, or configuration, our experienced team can develop a customized plan to meet your demands.

Our Anping County Ansheng Wire Meshes Product Co., Ltd. also provides on-site consultations and technical support to help you select the right product for your application.

Environmental and Safety Compliance

Our epoxy coated wire mesh is manufactured using environmentally friendly materials and processes, ensuring compliance with international safety and quality standards. The epoxy coating is free from harmful substances and meets the requirements of Anping County Ansheng Wire Meshes Product Co., Ltd.'s commitment to sustainability.

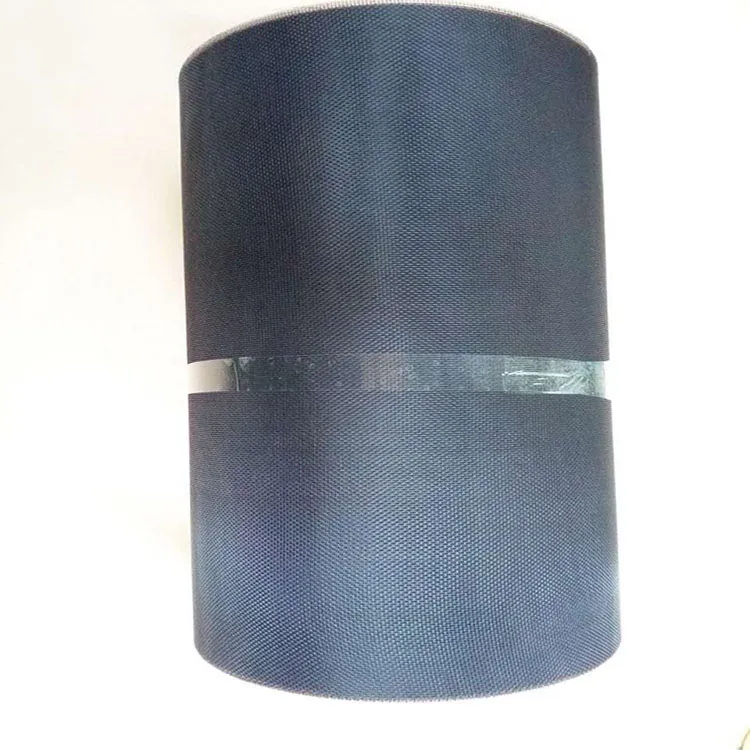

Product Packaging and Delivery

We ensure that our epoxy coated welded wire mesh is packaged securely to prevent damage during transportation. Our standard packaging includes:

- Waterproof and UV-Resistant Wrapping: Protects the mesh from moisture and sunlight exposure.

- Sturdy Cartons or Pallets: Ensures safe handling and storage during transit.

- Custom Labeling: Provides clear identification of product details and specifications.

We offer flexible shipping options, including sea freight, air freight, and land transport, to accommodate global delivery needs.

After-Sales Support and Technical Services

At Anping County Ansheng Wire Meshes Product Co., Ltd., we are committed to providing exceptional customer service. Our epoxy coated wire mesh comes with comprehensive after-sales support, including:

- Technical Consultation: Our experts are available to assist with product selection, installation, and troubleshooting.

- Warranty and Replacement: We offer a warranty period for all products, ensuring satisfaction and reliability.

- On-Site Training: We provide training sessions to help your team effectively use and maintain our products.

Contact Us for More Information

Ready to experience the benefits of epoxy coated wire mesh? Contact Anping County Ansheng Wire Meshes Product Co., Ltd. today to discuss your project requirements and receive a personalized quote.

- Email: sales@anshengfilterscreen.com

- Phone: +86-312-588-1234

- Website: www.anshengfilterscreen.com

- Product Page: Epoxy Coated Wire Mesh

FAQ

Q1: What are the main applications of epoxy coated wire mesh?

A: Our epoxy coated wire mesh is widely used in concrete reinforcement, industrial flooring, bridge construction, and chemical facilities due to its corrosion resistance and durability.

Q2: Can the epoxy coating be customized?

A: Yes, we offer custom coating colors and thicknesses to suit specific project requirements. Please contact our sales team for details.

Q3: How long does the epoxy coating last?

A: The lifespan of the epoxy coating depends on environmental conditions, but it typically lasts 10-15 years under normal usage. Our products are designed to provide long-term protection against corrosion.

Q4: Is the epoxy coated wire mesh environmentally friendly?

A: Yes, our products are manufactured using eco-friendly materials and processes, ensuring compliance with international environmental standards.

Q5: What is the minimum order quantity?

A: We offer flexible order quantities to accommodate both small and large projects. Please contact us for details on minimum order requirements.

Transform your construction and industrial projects with the superior performance of epoxy coated wire mesh. Contact Anping County Ansheng Wire Meshes Product Co., Ltd. today to learn more!

Post time: Jul . 20, 2025 23:40