At Anping County Ansheng Wire Meshes Product Co., Ltd., we specialize in delivering high-precision wire mesh discs that combine advanced manufacturing techniques with rigorous quality control. These mesh discs are engineered to meet the exacting demands of modern industrial applications, offering unparalleled accuracy, durability, and cost-effectiveness. This article explores the technical specifications, applications, and benefits of our single-layer wire mesh discs, supported by authoritative references and detailed product information.

Product Overview

Our wire mesh discs are designed for precision filtration, industrial screening, and structural applications. Each disc is crafted using high-quality materials such as stainless steel 304, stainless steel 201, stainless steel 316, and galvanized steel, ensuring exceptional corrosion resistance and mechanical strength. The manufacturing process involves advanced CNC machining equipment and a team of experienced technicians, guaranteeing consistent quality and accuracy.

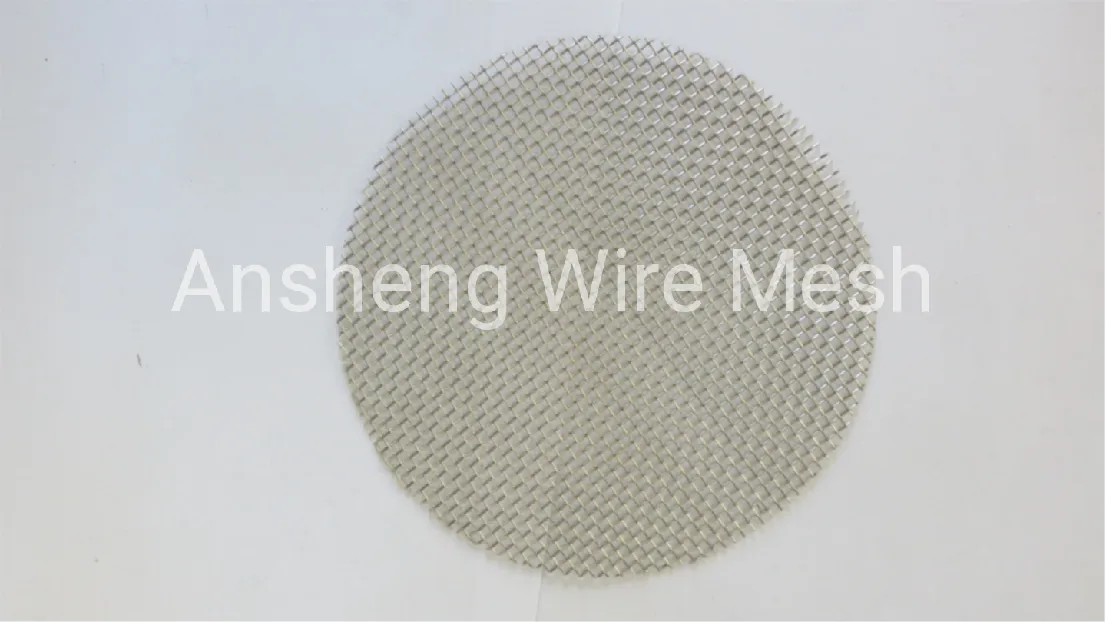

Image: High-quality wire mesh discs with precise edge finishing

Key Features and Advantages

1. Shape Regularity and Structural Integrity

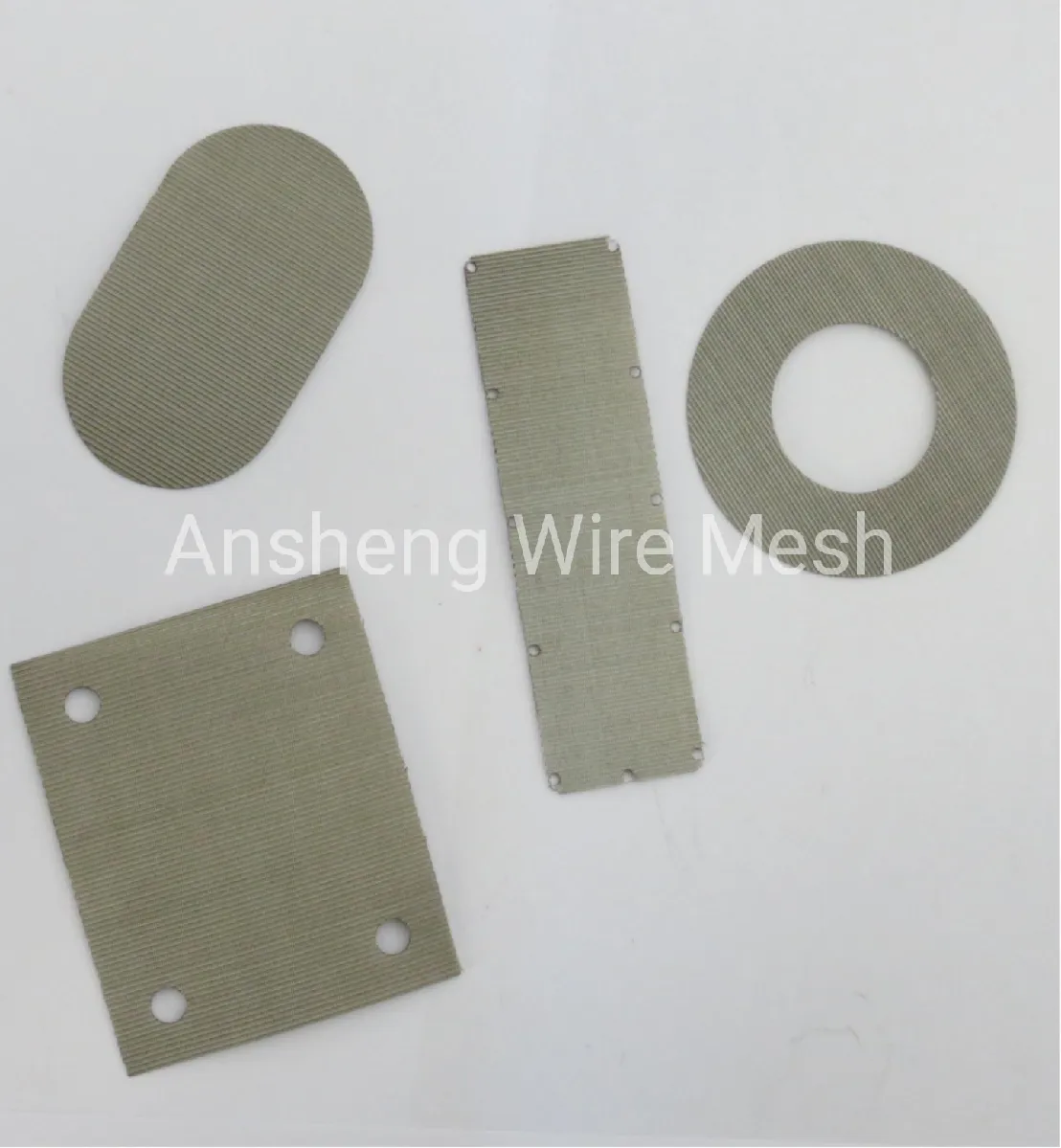

Our wire mesh discs are manufactured with meticulously controlled edge geometry, ensuring a regular shape without distortion or deformation. This precision simplifies installation and enhances stability during operation, making them ideal for applications requiring consistent performance under mechanical stress.

2. High-Quality Material Selection

We prioritize the use of high-purity raw materials, including premium-grade stainless steel and galvanized iron. These materials are selected for their corrosion resistance, strength, and toughness, ensuring long-term durability in harsh environments. For example, stainless steel 316 is particularly suited for marine and chemical processing applications due to its superior resistance to chloride corrosion.

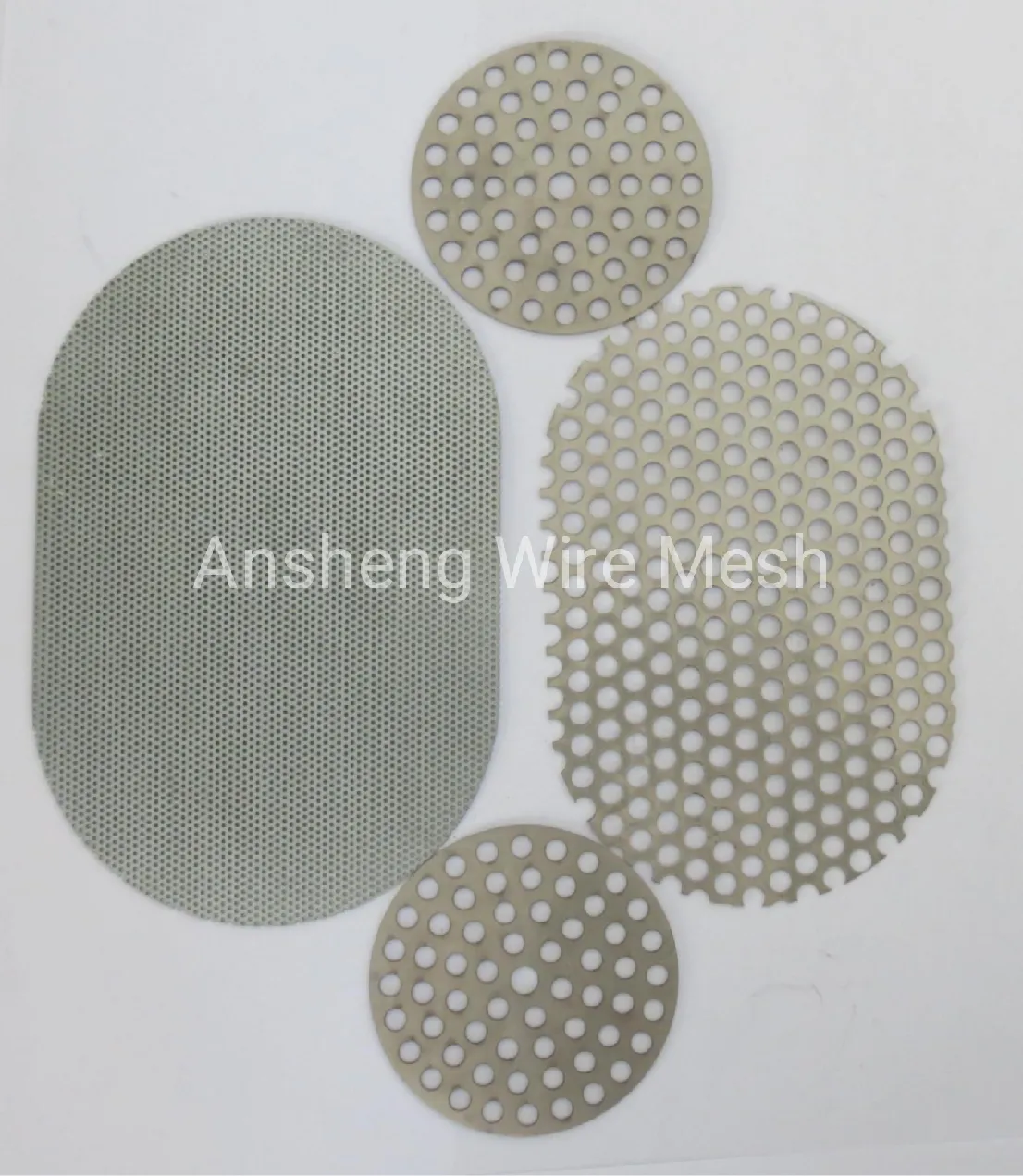

Image: Fine weaving of mesh sanding discs

3. Fine Weaving and Filtration Accuracy

The mesh is tightly woven to ensure uniform mesh sizes and eliminate defects such as skipped threads or leaks. This precision guarantees high filtration accuracy, making our wire mesh discs suitable for applications ranging from particle separation to liquid filtration. The consistent weave also enhances the aesthetic appeal of the final product.

4. Accurate Specifications and Customization

Each mesh disc is produced to meet exacting dimensional tolerances. Dimensions such as length, width, and aperture are meticulously controlled to ensure compatibility with other components and equipment. This level of precision reduces the risk of installation errors and minimizes the need for rework, saving time and costs for end-users.

Image: Custom-cut wire mesh discs for specialized applications

Technical Specifications

| Parameter | Details |

|---|---|

| Materials | Stainless steel 304, 201, 316, 316L, nickel N6, nickel 200, nickel N4, low-carbon steel, galvanized steel |

| Mesh Size Range | 1-635 mesh |

| Size Range | 1mm-1m |

| Shapes | Circular, square, oval, kidney-shaped, rectangular, and irregular shapes |

| Types | Woven wire mesh, perforated mesh, expanded metal mesh |

| Edge Finish | Smooth, burr-free, and precise |

Applications Across Industries

Our wire mesh discs are versatile and find applications in a wide range of industries:

- Industrial Filtration: Used in liquid and gas filtration systems to remove impurities and particulates.

- Construction and Architecture: Employed in building facades, ventilation systems, and structural reinforcements.

- Automotive and Aerospace: Integrated into engine filters, cabin air filters, and lightweight structural components.

- Medical and Pharmaceutical: Utilized in sterilization equipment and precision filtration devices.

- Food and Beverage: Applied in processing equipment for hygiene-critical environments.

Cost-Effective Customization

Unlike purchasing full rolls of mesh and cutting them in-house, which can lead to material waste and increased transportation costs, our custom-cut wire mesh discs are produced with zero waste and optimized logistics. This approach not only reduces material costs but also minimizes environmental impact by eliminating excess packaging and transportation emissions.

Company Background

Anping County Ansheng Wire Meshes Product Co., Ltd. is a leading manufacturer of wire mesh products based in Anping County, Hebei Province, China. With decades of experience in the industry, the company has established itself as a trusted provider of high-quality mesh sanding discs and filter discs. Their commitment to innovation, quality control, and customer satisfaction has earned them a reputation for excellence in the global market.

Authoritative References and Standards

The production and quality standards of our wire mesh discs align with international benchmarks for industrial materials. While the NIST (National Institute of Standards and Technology) does not directly regulate mesh specifications, its research on precision manufacturing and material science provides critical insights into the methodologies used to ensure accuracy and durability in industrial components. For example, NIST's work on material property testing underscores the importance of rigorous quality control in manufacturing processes.

References

NIST (National Institute of Standards and Technology). (n.d.). https://www.nist.gov

Conclusion

Our wire mesh discs represent the pinnacle of precision engineering and industrial innovation. By combining advanced manufacturing techniques, high-quality materials, and a commitment to customization, we deliver products that meet the exacting demands of modern industries. Whether you require mesh sanding discs for surface preparation or filter discs for critical filtration applications, our solutions are designed to exceed expectations. Explore our product page to discover how our wire mesh discs can enhance your operations.

Post time: Sep . 27, 2025 12:45