Stainless Welded Wire Mesh is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire mesh. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Stainless Welded Wire Mesh Overview

- Benefits & Use Cases of Stainless Welded Wire Mesh in Manufacturing of metal wire mesh

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Stainless Welded Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

Stainless Welded Wire Mesh Overview

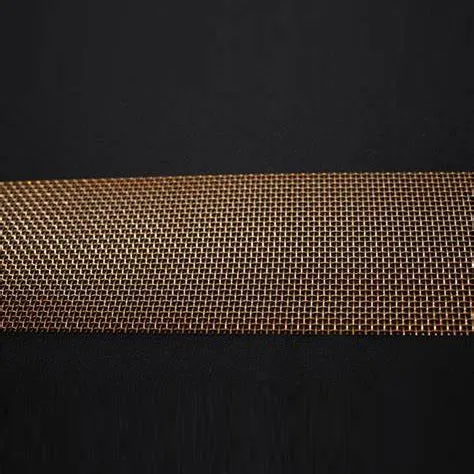

Stainless welded wire mesh is a rigid, flat panel or roll woven from stainless steel wire and permanently joined at each intersection through electric resistance welding. In the context of fabricated metal products and the broader Manufacturing of metal wire mesh, it delivers a dependable combination of structural integrity, corrosion resistance, and consistent aperture control. Common stainless grades include 304/304L for general industry and 316/316L for high-corrosion or food-contact environments. Mesh openings range from fine apertures up to large formats; popular specifications include 1/4" opening (often searched as 1 4 stainless steel mesh or 1/4 stainless steel mesh) for guarding and screening.

- Typical options: wire diameter ~0.5–6.0 mm, opening size ~6.35–100 mm, supplied as sheets or coils; custom framing, cut-to-size, and edge treatments available.

- Related formats—stainless woven mesh and stainless screen mesh—are often used when finer filtration or higher flexibility is required, while welded mesh is preferred for rigidity and load-bearing needs.

- Anping County Ansheng Wire Meshes Product Co., Ltd. manufactures tight-tolerance, high-flatness panels for industrial projects worldwide, aligning output with the demands of OEMs, EPC contractors, and maintenance teams.

Benefits & Use Cases of Stainless Welded Wire Mesh in Manufacturing of metal wire mesh

Across manufacturing plants and metal fabrication shops, stainless welded wire mesh is specified for machine guarding, safety partitions, material cages, ventilation screens, tray and rack fabrication, architectural infill panels, and conveyor or baking equipment. Compared with mild steel alternatives, stainless offers longer service life in damp or chemically active areas and eliminates routine repainting. When projects require flexibility or very fine openings, stainless woven mesh and stainless screen mesh complement welded panels, while agricultural enclosures sometimes call for stainless chicken wire. Ansheng provides guidance to help teams select the right mesh geometry and grade for each environment and load requirement.

- Competitive advantages: precise, square openings; high weld strength at intersections; excellent flatness for quick installation; compatibility with passivation or polishing for hygiene-critical zones.

- Popular specs like 1 4 stainless steel mesh deliver dependable visibility and airflow while maintaining operator safety around moving equipment.

- With deep expertise and flexible production, Anping County Ansheng Wire Meshes Product Co., Ltd. fulfills OEM drawings, short-run prototypes, and volume orders on deadline.

Cost, Maintenance & User Experience

Total cost of ownership favors stainless welded wire mesh when lifecycle and maintenance are factored in. While upfront pricing may exceed painted carbon steel, stainless significantly reduces repainting, coating touch-ups, and corrosion-related downtime. It cleans easily with standard plant procedures and resists abrasion from routine handling. Specifying welded mesh panels with precise flatness shortens installation time and lowers field modification costs for fabricators and integrators. Procurement teams also value supply continuity, packaging that prevents deformation, and consistent weld penetration—attributes that directly affect scrap rates and rework.

- Durability and ROI: extended service life in high-moisture and chemical washdown areas reduces replacement frequency and inventory carrying costs.

- User feedback: customers in the fabricated metal products sector commonly report fewer panel adjustments at install, improved visual uniformity on architectural jobs, and smoother throughput in guard system builds.

Sustainability & Market Trends in manufacturing

Industrial buyers are prioritizing materials that support decarbonization goals, longer asset life, and recyclability. Stainless steel aligns with these trends: it is highly recyclable, requires no solvent-based coatings for corrosion protection, and enables long maintenance intervals. Additionally, the shift to hygienic, easy-to-clean surfaces in food, beverage, and pharmaceutical plants favors stainless welded wire mesh over painted guards. Regulations and customer standards increasingly consider product durability and end-of-life recovery—areas where stainless solutions perform well compared with coated substrates.

- Anping County Ansheng Wire Meshes Product Co., Ltd. supports responsible sourcing, efficient production scheduling to minimize waste, and packaging approaches that reduce damage and rework.

- As demand grows across OEM guarding, architectural metalwork, and process equipment, Ansheng’s capabilities in welded mesh, stainless woven mesh, stainless screen mesh, and related formats position the company to guide B2B decision makers toward durable, eco-aligned specifications.

Conclusion on Stainless Welded Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

From safety guarding and partitions to racks, trays, and architectural infill, stainless welded wire mesh delivers reliability, corrosion resistance, and cleanability that align with modern manufacturing demands. Backed by precise welding, flatness control, and material options that include 304/316 grades, Anping County Ansheng Wire Meshes Product Co., Ltd. is a trusted partner for fabricators, OEMs, and plant engineers. Whether your project calls for welded panels, stainless woven mesh, stainless screen mesh, or even stainless chicken wire for specialty enclosures, our team can recommend the optimal specification.

- Choose Stainless Welded Wire Mesh to improve durability, safety, and total lifecycle value across the Fabricated metal products sector.

- Ansheng’s reputation is built on consistent quality, flexible production, and responsive service.

- Contact us: email: sales@anshengwiremesh.com — Visit our website: https://www.anshengfilterscreen.com

Post time: Nov . 04, 2025 08:15