- Market Growth and Industrial Demand Metrics

- Engineering Advantages of Modern Perforation Technologies

- Evaluation of Major Industry Providers

- Custom Solutions for Specialized Applications

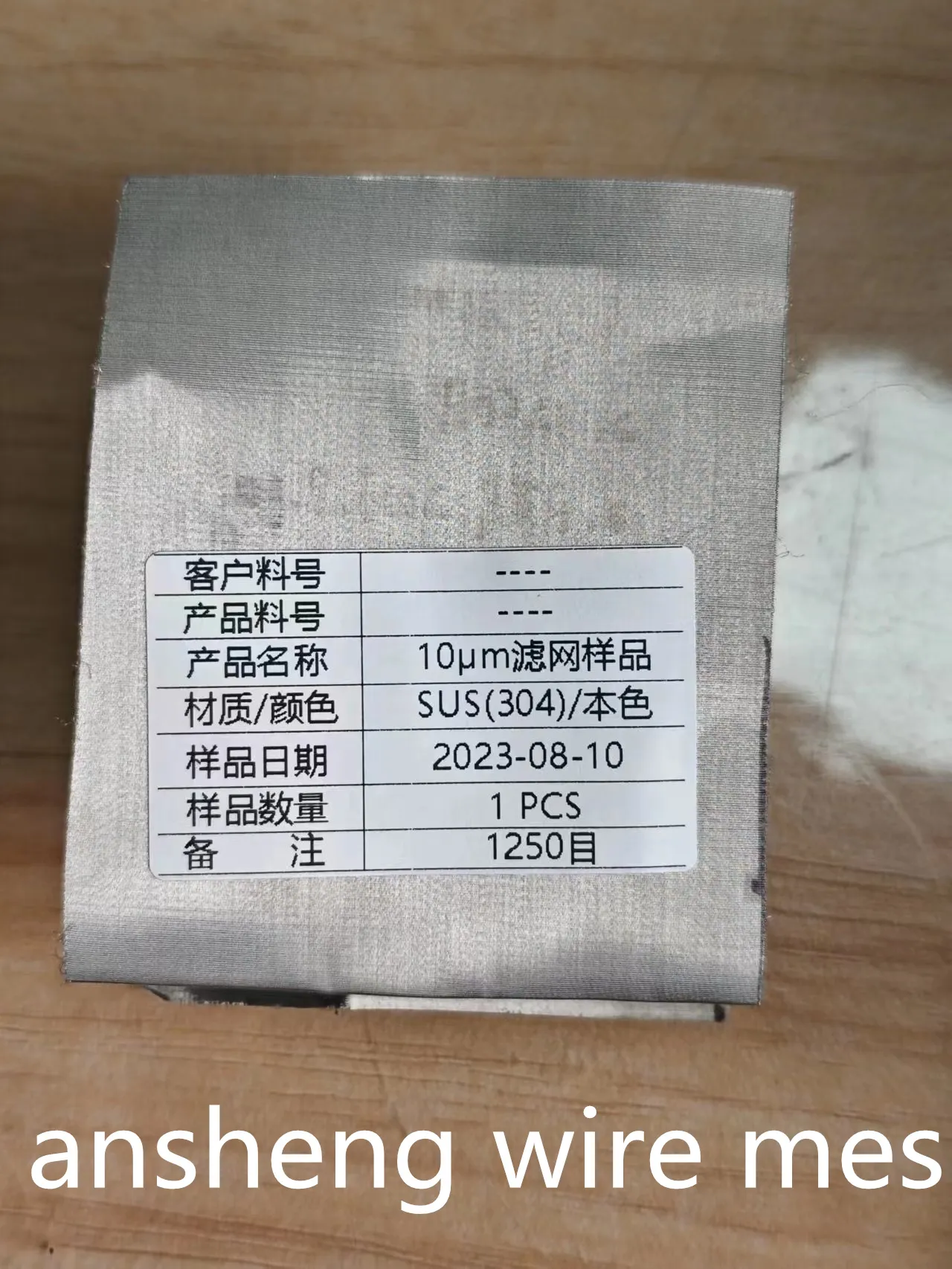

- Material Specifications and Manufacturing Standards

- Industry-Specific Implementation Case Studies

- Selection Strategy for Stainless Perforated Sheet Suppliers

(stainless perforated sheet suppliers)

Critical Factors When Choosing Stainless Perforated Sheet Suppliers

The industrial supply chain for perforated metals relies heavily on specialized manufacturing capabilities. Demand surged by 7.2% annually since 2020, with architectural and filtration sectors accounting for 63% of global consumption. Leading procurement managers prioritize three core criteria: consistent perforation tolerances within ±0.05mm, ASTM A480/A666 material compliance, and sub-72-hour lead times for standard orders.

Engineering Advantages of Modern Perforation Technologies

Contemporary manufacturing breakthroughs enable complex hole patterns previously impossible. CNC-controlled punch presses now achieve 900+ strikes/minute with positional accuracy of 0.01mm. Laser perforation systems manage micro-perforations down to 0.3mm diameter while minimizing thermal distortion. These technologies yield sheets with open area ratios from 3% to 70% without compromising structural integrity. Enhanced turbulence characteristics in filtration models demonstrate 23% higher particulate capture efficiency compared to woven alternatives.

Evaluating Perforated Steel Sheet Suppliers

| Supplier | Production Capacity (sq ft/month) | Material Range | Lead Time (Std Orders) | Tolerance Standards |

|---|---|---|---|---|

| Perforated Metals Inc. | 450,000 | 304L, 316L, 430 | 48 hours | ASTM E290 |

| Industrial Perforators Group | 290,000 | 304, 316Ti, Duplex | 72 hours | ISO 2768-1 |

| Precision Perforating Co. | 180,000 | 304, 310S, 321 | 5 business days | ASME BPE |

Third-party audits reveal critical differentiators: Top-tier perforated sheet metal suppliers maintain zero cross-contamination protocols when processing different alloys. Certifications like NADCAP AC7114 for aerospace applications separate industry leaders from standard manufacturers.

Custom Solutions for Specialized Applications

For architectural projects like the Odéon Louvre façade, suppliers developed custom staggered hexagonal perforations at 56% open area ratio. In pharmaceutical settings, specialized perforated sheet metal suppliers created micro-perf layouts enabling 0.02μm particulate retention. Chemical processing plants increasingly specify custom duplex steel perforations with electropolishing, reducing maintenance frequency by 40%.

Material Specifications and Manufacturing Standards

Stainless steel perforated sheets perform optimally when manufactured to precise material specifications. Key considerations include:

- Alloy selection based on chloride exposure levels

- Post-perforation treatments like passivation

- Burr control measures per ASTM E1817

- Non-destructive testing protocols

Leading perforated steel sheet suppliers now employ inline laser metrology during production, enabling real-time thickness variation detection below 0.015mm. This eliminates downstream fabrication issues in critical tolerance applications.

Industry-Specific Implementation Case Studies

Automotive OEMs reduced cabin noise by 8dB using perforated sheets with precisely calculated open area patterns. Global infrastructure projects are implementing architectural facades with integrated airflow patterns, reducing cooling loads by 22%. Food processing plants utilizing 316L stainless perforated screens report 30% longer service life compared to traditional screens.

Strategic Selection of Perforated Sheet Metal Suppliers

Aerospace filtration projects validate that premium stainless perforated sheet suppliers

maintain certified traceability from raw material to final product. Forward-thinking suppliers have adopted predictive modeling to simulate fluid dynamics outcomes before production. Procurement specialists should verify tier-level certifications and request material test reports for critical applications.

(stainless perforated sheet suppliers)

FAQS on stainless perforated sheet suppliers

Here are 5 stainless perforated sheet supplier FAQs in HTML format:Q: What materials do you offer for perforated sheets?

A: We supply perforated sheets in various stainless steel grades including 304 and 316. Other options include carbon steel, aluminum, and specialty alloys. Material selection depends on your specific application requirements.

Q: Can I request custom perforation patterns?

A: Yes, we specialize in custom hole shapes, sizes, and layouts. Our laser-cutting technology accommodates unique designs from round/square holes to complex geometric patterns. Standard templates are also available for common applications.

Q: What industries use your perforated metal sheets?

A: Our products serve architectural, industrial, and filtration sectors. Common applications include machinery guards, acoustic panels, screening systems, and decorative facades. We also supply specialized solutions for food processing and chemical plants.

Q: How do you ensure product quality?

A: All perforated sheets undergo strict quality control checks including material certification and dimensional accuracy verification. We comply with international standards like ASTM/ASME and provide mill test reports. Our automated inspection systems guarantee consistent hole precision.

Q: What are your minimum order quantities?

A: MOQs vary based on material type and hole pattern complexity. We accommodate both prototype requests and bulk production orders. Most standard patterns have no minimum quantity, while custom designs may require slightly higher volumes.

Post time: Jun . 10, 2025 05:41