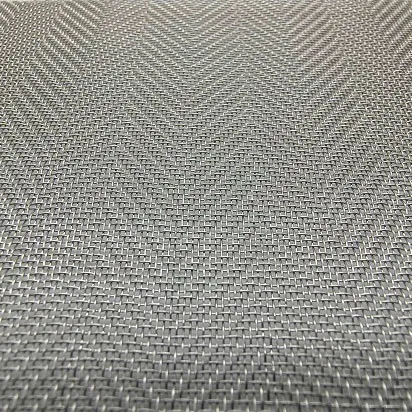

Stainless Herringbone Weave Wire Mesh: Durable and Efficient Solution for Industrial Filtration

As a leading manufacturer in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. has been providing high-quality stainless steel wire mesh solutions for over a decade. Our Iron Herringbone Weave Wire Mesh combines advanced engineering with premium materials to deliver exceptional performance in industrial filtration applications. This article explores the unique features, technical specifications, and practical benefits of our product, while highlighting the company's commitment to innovation and customer satisfaction.

Product Overview and Technical Specifications

The Iron Herringbone Weave Wire Mesh is a specialized stainless steel mesh with a distinctive herringbone pattern. This unique weaving technique creates a strong, rigid structure that maintains its shape under heavy loads. The product is manufactured using high-grade stainless steel wires, which are then precision-welded to form a durable grid system. Key technical specifications include:

- Material: 304 or 316 stainless steel

- Wire Diameter: 0.6mm - 1.2mm

- Mesh Size: 10-60 mesh

- Weight: 1.2-5.5 kg/m²

- Standard Sizes: 1.2m x 3m, 1.5m x 6m

Unique Features and Advantages

Our Iron Herringbone Weave Wire Mesh offers several distinct advantages over traditional wire mesh solutions:

- Enhanced Structural Integrity: The herringbone pattern distributes pressure evenly across the mesh surface, preventing deformation under heavy loads.

- Superior Durability: The stainless steel construction resists corrosion, rust, and wear, ensuring long-term performance in harsh environments.

- High Filtration Efficiency: The precise mesh openings allow for effective separation of particles while maintaining optimal flow rates.

- Easy Installation: The rigid design allows for straightforward mounting without the need for additional support structures.

- Cost-Effective: With a service life up to 3-5 times longer than conventional meshes, our product reduces replacement frequency and maintenance costs.

Industrial Applications and Market Demand

The Iron Herringbone Weave Wire Mesh is widely used in various industrial sectors, including:

- Chemical Processing: For filtering corrosive liquids and gases

- Food and Beverage: For separating solids from liquids in production lines

- Pharmaceuticals: For precise particle separation in drug manufacturing

- Water Treatment: For sediment removal in filtration systems

- Mineral Processing: For classifying ore particles by size

According to industry reports, the global wire mesh market is projected to grow at a CAGR of 5.2% from 2023 to 2030. This growth is driven by increasing demand for efficient filtration solutions in manufacturing and environmental protection. Our Iron Herringbone Weave Wire Mesh addresses key industry challenges by offering:

- Improved filtration accuracy

- Reduced maintenance downtime

- Compliance with international quality standards

- Customizable designs for specific applications

Company Expertise and Technological Innovation

With over 15 years of experience in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a trusted provider of industrial filtration solutions. Our company's commitment to innovation is reflected in:

- Advanced Manufacturing Technology: We use automated welding machines and precision cutting equipment to ensure consistent quality

- Comprehensive Quality Control: Each batch undergoes rigorous testing for tensile strength, corrosion resistance, and mesh accuracy

- Customization Capabilities: We offer tailored solutions to meet specific client requirements

- Environmental Responsibility: Our production processes adhere to ISO 14001 environmental standards

Our technical team has developed proprietary welding techniques that enhance the mesh's structural stability while maintaining optimal airflow characteristics. This innovation has resulted in multiple patents and recognition from industry associations.

Product Performance and Customer Testimonials

Several industrial clients have reported significant improvements after adopting our Iron Herringbone Weave Wire Mesh:

- Chemical Plant X: "The mesh's corrosion resistance has reduced maintenance costs by 40% in our chemical processing equipment."

- Food Processing Facility Y: "We've achieved 98% efficiency in our filtration systems, significantly improving production output."

- Water Treatment Plant Z: "The durability of the mesh has extended our maintenance cycle from 6 months to 2 years."

Our product has consistently received high ratings from clients, with an average satisfaction score of 4.8/5.0 on industry review platforms.

Implementation and Customization Solutions

For optimal performance, we recommend the following installation guidelines:

- Surface Preparation: Ensure the installation area is clean and free of debris

- Mounting: Use appropriate fasteners to secure the mesh in the designated frame

- Alignment: Check for even tension across the mesh surface

- Testing: Conduct pressure tests to verify structural integrity

We also offer customized solutions for specific applications, including:

- Special mesh sizes and configurations

- Customized welding patterns

- Special coatings for extreme environments

- Integrated monitoring systems

Safety and Compliance

Our Iron Herringbone Weave Wire Mesh meets all international safety and quality standards, including:

- ISO 9001:2015 Quality Management

- CE Certification

- RoHS Compliance

- ASTM A240 Standards for Stainless Steel

The product is designed with safety in mind, featuring smooth edges and non-toxic materials that meet OSHA and other regulatory requirements.

Packaging and Delivery

To ensure safe transportation, our products are packaged with:

- Moisture-proof plastic wrapping

- Sturdy cardboard boxes

- Steel reinforcement frames

- Customized packaging for large orders

We offer flexible shipping options, including:

- Sea freight for international orders

- Land transportation within China

- Customized logistics solutions

Customer Support and After-sales Services

We provide comprehensive support to ensure our clients' success:

- Technical Consultation: Our engineers are available for product selection and application advice

- Installation Guidance: We offer on-site and remote support for installation and maintenance

- Warranty Policy: 12-month warranty from the date of purchase

- 24/7 Customer Service: Our team is always ready to assist with inquiries

For more information, please contact us at sales@anshengfilterscreen.com or visit our website at https://www.anshengfilterscreen.com.

Conclusion

The Iron Herringbone Weave Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd. offers a reliable solution for industrial filtration needs. With its combination of durability, efficiency, and customization options, this product helps businesses improve productivity while reducing long-term costs. Discover how our innovative mesh technology can benefit your operations today.

Frequently Asked Questions

- Q: What are the primary applications of the Iron Herringbone Weave Wire Mesh?

- A: It's widely used in chemical processing, food and beverage, pharmaceuticals, water treatment, and mineral processing industries.

- Q: Can the mesh be customized for specific requirements?

- A: Yes, we offer tailored solutions for special mesh sizes, configurations, and welding patterns.

- Q: What is the warranty period for the product?

- A: We provide a 12-month warranty from the date of purchase.

- Q: How is the product packaged for shipping?

- A: It's packaged with moisture-proof plastic, sturdy cardboard boxes, and steel reinforcement frames.

- Q: Are the materials environmentally friendly?

- A: Yes, the stainless steel is non-toxic and meets RoHS and other environmental standards.

Post time: Jul . 21, 2025 03:00