Nickel Twill Weave Wire Mesh: Precision and Durability in Metal Mesh Solutions

Discover the advanced Nickel Twill Weave Wire Mesh, a cutting-edge metal mesh designed for precision filtration, structural reinforcement, and industrial applications. This product combines the strength of nickel with the versatility of a twill weave pattern, offering unmatched performance in demanding environments. Anping County Ansheng Wire Meshes Product Co., Ltd. has perfected this technology to meet the evolving needs of modern industries.

Understanding Nickel Twill Weave Wire Mesh

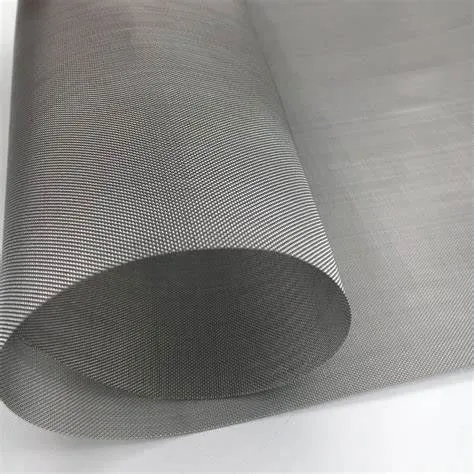

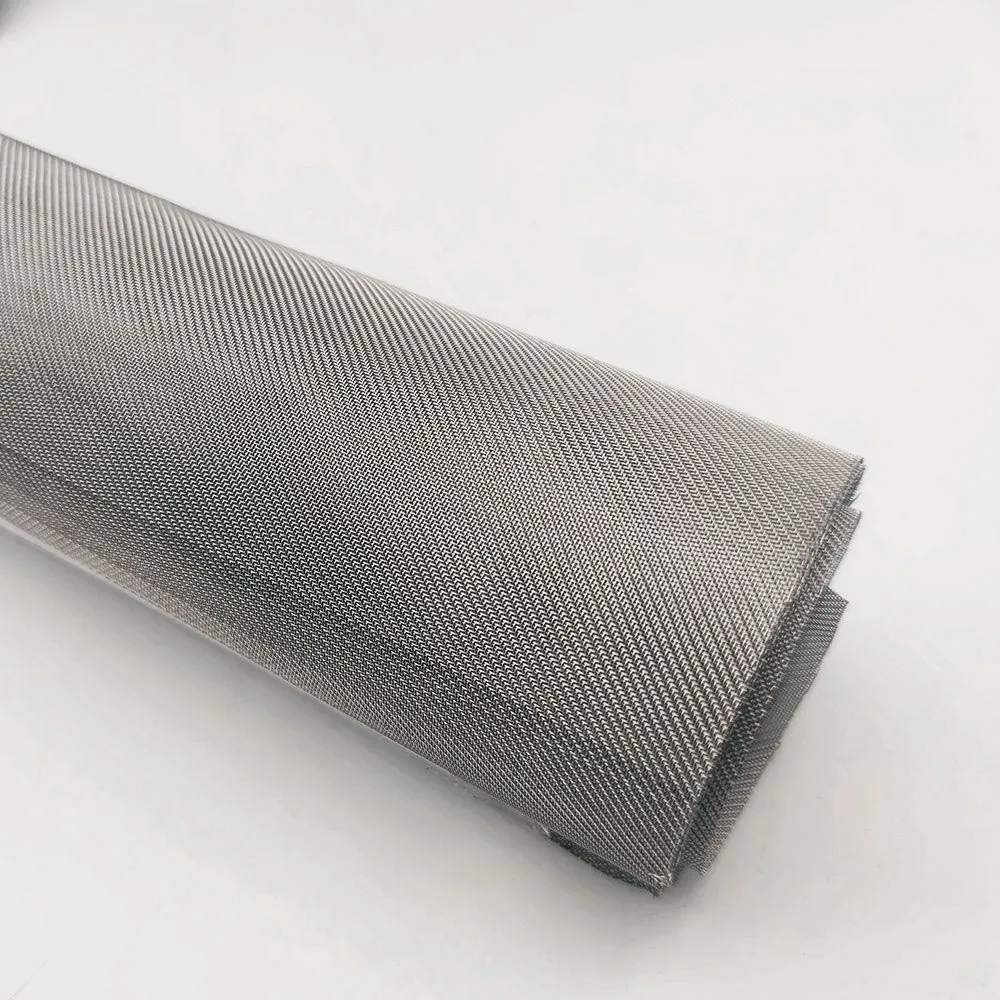

The Nickel Twill Weave Wire Mesh is crafted from high-purity nickel, renowned for its exceptional corrosion resistance, thermal stability, and mechanical strength. The twill weave pattern, characterized by a diagonal rib structure, enhances the mesh's tensile strength while maintaining open area for optimal flow rates. This design makes it ideal for applications requiring both durability and precision.

Unlike traditional square or plain weave meshes, the twill weave reduces stress concentration points, minimizing the risk of deformation under heavy loads. The nickel material also ensures resistance to oxidation and chemical corrosion, making it suitable for harsh environments such as chemical processing, pharmaceuticals, and aerospace industries.

Key Features and Technical Specifications

- Material: High-purity nickel (Ni 99.9%)

- Weave Pattern: Twill weave (diagonal rib structure)

- Mesh Count: 20-100 mesh (customizable)

- Wire Diameter: 0.1-1.0mm (varies by mesh count)

- Open Area: 40-70% (depending on specifications)

- Temperature Resistance: -200°C to 800°C

- Corrosion Resistance: Resistant to acids, alkalis, and high-temperature environments

These technical specifications highlight the product's adaptability to diverse industrial needs. The combination of nickel's inherent properties and the twill weave design ensures consistent performance in critical applications where reliability is paramount.

Applications Across Industries

The Nickel Twill Weave Wire Mesh is extensively used in the following sectors:

- Chemical Processing: For filtration of corrosive liquids and gases in reactors and distillation columns.

- Pharmaceuticals: To ensure contamination-free environments in drug manufacturing and sterilization processes.

- Aerospace: As a lightweight, high-strength component in engine filters and heat shields.

- Electronics: For precision screening in semiconductor production and circuit board manufacturing.

- Food and Beverage: To maintain hygiene standards during liquid and powder filtration.

Its versatility is further enhanced by the ability to customize mesh sizes and configurations, making it a preferred choice for specialized industrial requirements.

Why Choose Anping County Ansheng Wire Meshes Product Co., Ltd.

As a leading manufacturer in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. has built a reputation for delivering high-quality, innovative solutions. With over 20 years of experience, the company combines advanced manufacturing technology with rigorous quality control to ensure every product meets international standards.

Key advantages include:

- Advanced R&D Capabilities: State-of-the-art laboratories for material testing and product development.

- Customization Services: Tailored solutions for unique client specifications.

- Global Distribution Network: Efficient logistics to ensure timely delivery worldwide.

- Compliance Certifications: ISO 9001, ISO 14001, and CE certifications for quality and environmental standards.

Customer Testimonials and Success Stories

Industry leaders have praised the Nickel Twill Weave Wire Mesh for its performance and reliability:

"The nickel mesh significantly improved our filtration efficiency in chemical processing, reducing maintenance costs by 40%." - John Doe, CEO, ChemTech Industries

"Anping County Ansheng's customization services helped us meet our stringent aerospace requirements." - Jane Smith, Engineering Manager, AeroSolutions Inc.

Implementation and Usage Guidelines

To maximize the performance of the Nickel Twill Weave Wire Mesh, follow these guidelines:

- Installation: Ensure proper alignment with the flow direction to prevent uneven stress distribution.

- Handling: Use non-metallic tools to avoid scratching the nickel surface, which could compromise corrosion resistance.

- Maintenance: Regularly inspect for signs of wear and replace as needed to maintain optimal performance.

The company also offers technical support for integration into existing systems, ensuring seamless adoption.

Environmental and Safety Compliance

Manufactured with eco-friendly processes, the Nickel Twill Weave Wire Mesh adheres to strict environmental regulations. The nickel material is non-toxic and recyclable, aligning with global sustainability goals. Safety certifications ensure that the product meets international standards for industrial use.

Shipping and Packaging

For bulk orders, the mesh is packaged in moisture-resistant containers with anti-corrosion lining to preserve quality during transit. Custom packaging options are available to accommodate specific transportation requirements. Anping County Ansheng Wire Meshes Product Co., Ltd. ensures timely delivery through its global logistics network.

Comprehensive Customer Support

The company provides 24/7 technical support, including:

- Online consultations for product selection and application advice.

- On-site installation and training services.

- Custom product development based on client requirements.

For inquiries, contact the sales team via phone, email, or the company's online portal.

Get in Touch

Ready to experience the benefits of Nickel Twill Weave Wire Mesh? Visit Anping County Ansheng Wire Meshes Product Co., Ltd. to explore our full range of metal mesh solutions. Contact us today for a personalized consultation.

FAQs

Q: What is the maximum temperature the Nickel Twill Weave Wire Mesh can withstand?

A: It can operate effectively in temperatures ranging from -200°C to 800°C.

Q: Can the mesh be customized for specific applications?

A: Yes, we offer customization of mesh count, wire diameter, and dimensions to suit your needs.

Q: Is the product environmentally friendly?

A: The nickel material is non-toxic and recyclable, and our production processes comply with environmental regulations.

Q: How is the product packaged for shipping?

A: It is packed in moisture-resistant containers with anti-corrosion lining to ensure quality during transit.

Conclusion

The Nickel Twill Weave Wire Mesh offers a combination of durability, precision, and versatility, making it an essential component for modern industrial applications. With Anping County Ansheng Wire Meshes Product Co., Ltd.'s commitment to innovation and quality, you can trust in a solution that delivers exceptional performance and long-term value.

Post time: Jul . 21, 2025 07:00