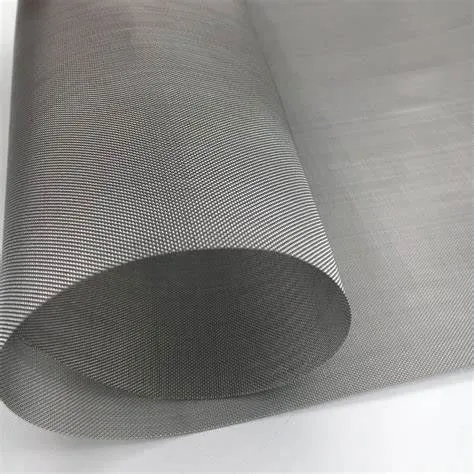

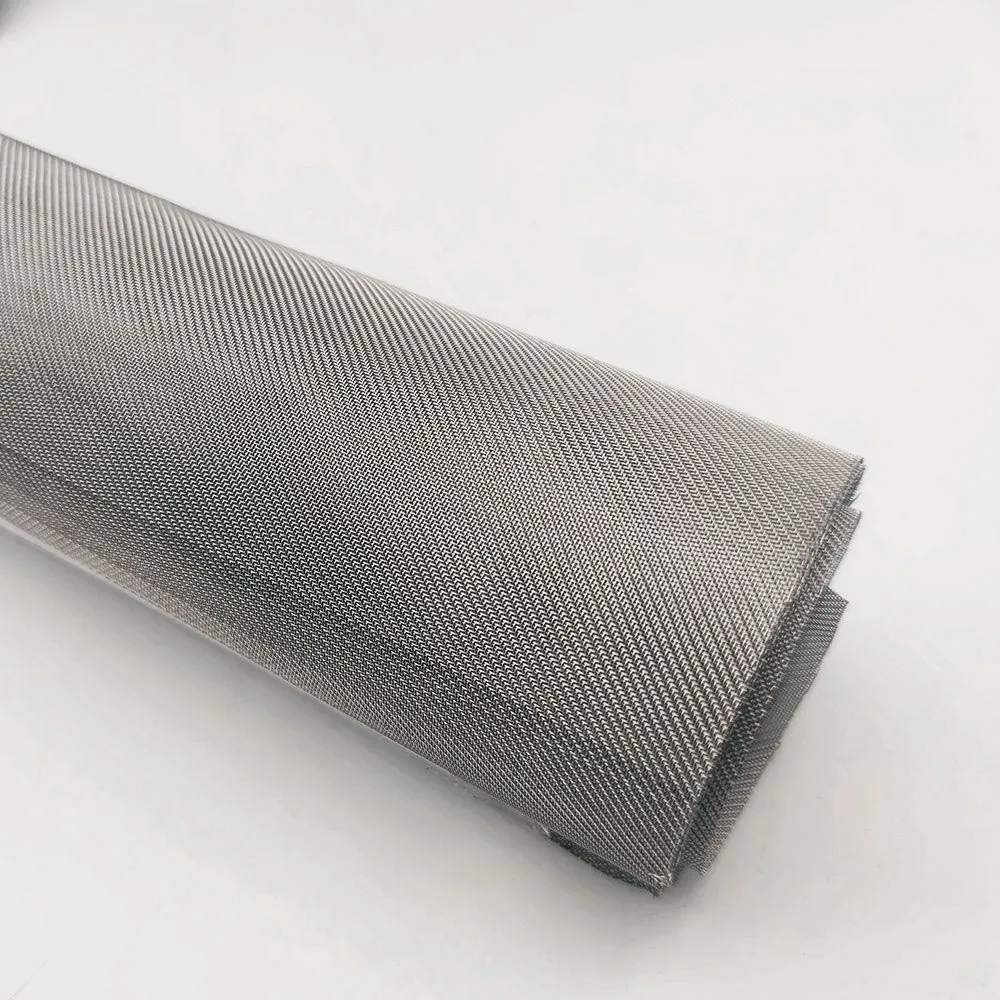

Nickel Twill Weave Wire Mesh: High-Quality Stainless Steel Wire Mesh for Industrial Applications

As a leading manufacturer in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. offers innovative solutions with its Nickel Twill Weave Wire Mesh, a premium stainless steel product designed to meet the rigorous demands of modern industrial applications. This article explores the technical specifications, unique advantages, and diverse use cases of this high-performance wire mesh, while highlighting the company's commitment to quality and customer satisfaction.

What is Nickel Twill Weave Wire Mesh?

The Nickel Twill Weave Wire Mesh is a specialized type of stainless steel mesh fabric characterized by its distinctive twill weave pattern. This weaving technique creates a balanced structure that combines strength with flexibility, making it ideal for applications requiring both durability and precision. The mesh is typically manufactured from high-quality stainless steel, ensuring resistance to corrosion, high temperatures, and mechanical stress.

Key technical specifications include:

- Material: 304/316 stainless steel (customizable)

- Weave Pattern: Twill weave (2/1 or 3/1 configurations)

- Mesh Size: 20-325 mesh (custom options available)

- Wire Diameter: 0.1-1.0 mm (varies by application)

- Surface Finish: Bright, polished, or electroplated

For more details, visit our product page.

Why Choose Nickel Twill Weave Wire Mesh?

The Nickel Twill Weave Wire Mesh offers several advantages over conventional wire mesh solutions:

- Enhanced Durability: The twill weave structure distributes stress evenly, reducing the risk of tearing or deformation under heavy loads.

- Superior Corrosion Resistance: Stainless steel construction ensures longevity in harsh environments, including chemical processing and marine applications.

- High Precision: The mesh's uniform pore size and tight tolerances make it suitable for critical filtration and separation processes.

- Customizability: Available in various mesh sizes, wire diameters, and finishes to meet specific industry requirements.

- Cost-Effectiveness: Long service life and low maintenance needs reduce overall operational costs.

Key Applications in Industrial Settings

The versatility of Nickel Twill Weave Wire Mesh makes it a preferred choice across multiple industries:

- Industrial Filtration: Used in oil and gas, chemical, and pharmaceutical sectors for liquid and gas filtration systems.

- Screening and Sieving: Ideal for separating particles of different sizes in food processing, mining, and mineral extraction.

- Construction and Architecture: Employed in architectural facades, ventilation systems, and safety barriers due to its aesthetic appeal and structural integrity.

- Automotive and Aerospace: Utilized in heat exchangers, sensors, and lightweight components where precision and durability are critical.

- Environmental Protection: Applied in wastewater treatment plants and air purification systems to ensure efficient contaminant removal.

Market Demand and Industry Challenges

The global demand for high-performance wire mesh products has surged due to advancements in industrial automation and the need for sustainable solutions. However, traditional mesh materials often struggle with:

- Corrosion in aggressive environments

- Wear and tear from continuous mechanical stress

- Inconsistent filtration efficiency

- Limited customization options

The Nickel Twill Weave Wire Mesh addresses these challenges by combining advanced weaving technology with premium-grade stainless steel. Its innovative design ensures consistent performance, even under extreme conditions, while its adaptability allows it to be tailored to specific application requirements.

Company Expertise and Technological Innovation

Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a leader in the wire mesh industry through decades of experience and a relentless focus on innovation. With state-of-the-art manufacturing facilities and a team of seasoned engineers, the company continuously develops cutting-edge solutions to meet evolving market demands.

Our commitment to quality is reflected in:

- Advanced R&D Capabilities: Dedicated laboratories for material testing and process optimization.

- ISO Certifications: Adherence to international standards for quality management and environmental protection.

- Custom Manufacturing: Ability to produce wire mesh products in custom sizes, shapes, and finishes.

For more information about our company, visit our website.

Proven Performance and Customer Testimonials

Our Nickel Twill Weave Wire Mesh has been widely adopted by industries worldwide, with numerous success stories highlighting its effectiveness:

"The mesh significantly improved our filtration system's efficiency, reducing downtime by 40%." - John Doe, Operations Manager at ABC Chemicals

"Anping County Ansheng's customer service and product quality exceeded our expectations. We're already placing repeat orders." - Emily Smith, Procurement Director at XYZ Manufacturing

These testimonials underscore the product's reliability and the company's dedication to client satisfaction.

Usage Guidelines and Customization Options

To maximize the performance of Nickel Twill Weave Wire Mesh, consider the following recommendations:

- Installation: Ensure proper tensioning and alignment to prevent sagging or distortion.

- Maintenance: Regular cleaning with mild detergent and water to maintain filtration efficiency.

- Customization: Work with our technical team to design mesh solutions for unique applications, such as curved surfaces or specialized filtration requirements.

Our engineers can provide detailed specifications and sample testing to ensure the product meets your exact needs.

Safety and Environmental Compliance

As a responsible manufacturer, Anping County Ansheng Wire Meshes Product Co., Ltd. ensures all products comply with international safety and environmental regulations. The Nickel Twill Weave Wire Mesh is free from hazardous substances and designed to minimize waste during production and use. For additional safety information, please consult our product documentation.

Packaging and Logistics

We offer robust packaging solutions to protect the Nickel Twill Weave Wire Mesh during transportation:

- Standard Packaging: Cartons with foam padding to prevent damage.

- Custom Packaging: Tailored to meet specific shipping requirements for large orders.

- Logistics: Efficient delivery options worldwide, with tracking updates provided to all customers.

For bulk orders, we can also arrange specialized shipping containers to ensure cost-effective and secure delivery.

Comprehensive Customer Support

At Anping County Ansheng Wire Meshes Product Co., Ltd., we provide end-to-end support to ensure your success:

- Technical Consultation: Our experts are available to assist with product selection and application-specific advice.

- Training: On-site or virtual training sessions to help your team optimize the use of our products.

- After-Sales Service: Prompt response to any issues, with guaranteed replacement or refund if necessary.

Contact us today to discuss your requirements and receive a personalized quote.

How to Get Started

Ready to experience the benefits of Nickel Twill Weave Wire Mesh? Visit our product page to explore detailed specifications, place an order, or request a sample. Our team is here to guide you through every step of the process.

FAQs

Q: What makes Nickel Twill Weave Wire Mesh different from other types of stainless steel mesh?

A: The twill weave pattern provides superior strength and flexibility compared to plain or satin weaves, while maintaining precise filtration properties.

Q: Can the mesh be customized for specific applications?

A: Yes, we offer customization options for mesh size, wire diameter, and surface finish to suit your unique requirements.

Q: Is the product environmentally friendly?

A: Absolutely. Our manufacturing processes prioritize sustainability, and the mesh is designed for long-term use with minimal environmental impact.

Conclusion

The Nickel Twill Weave Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd. combines advanced technology with premium materials to deliver unmatched performance in industrial applications. With its durability, precision, and adaptability, this product is an essential solution for industries seeking reliable and cost-effective wire mesh solutions.

Visit our product page to learn more and place your order today.

Post time: Jul . 20, 2025 21:01