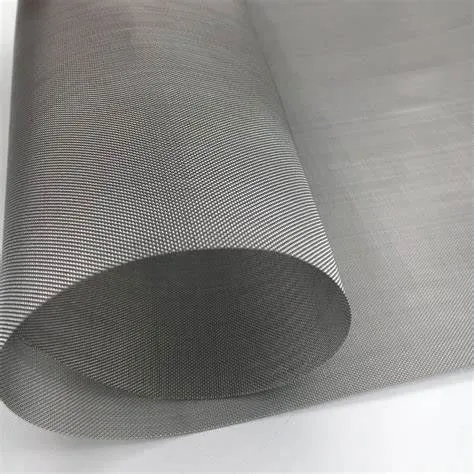

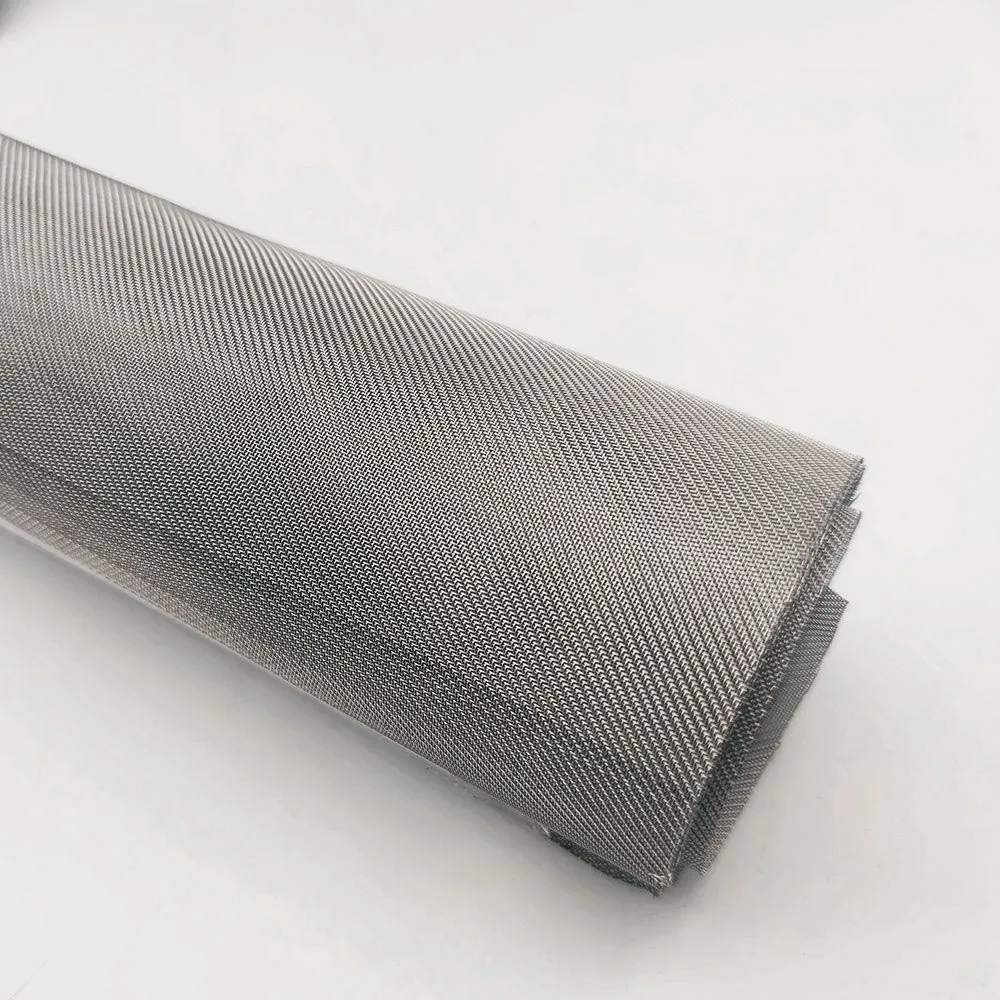

Nickel Twill Weave Wire Mesh: Advanced Stainless Steel Mesh Fabric for Industrial Applications

At Anping County Ansheng Wire Meshes Product Co., Ltd., we specialize in providing high-performance Nickel Twill Weave Wire Mesh, a cutting-edge stainless steel mesh fabric designed to meet the demanding requirements of modern industrial applications. Our product combines advanced engineering with durable materials to deliver exceptional strength, corrosion resistance, and versatility. Whether you're in manufacturing, filtration, or construction, our stainless woven wire mesh offers a reliable solution to enhance efficiency and longevity in your operations.

Product Overview and Core Features

The Nickel Twill Weave Wire Mesh is a premium stainless steel grid mesh engineered for industrial applications requiring precision and durability. This product is crafted from high-quality stainless steel, ensuring resistance to corrosion, high temperatures, and mechanical stress. The unique twill weave pattern enhances flexibility while maintaining structural integrity, making it ideal for a wide range of applications.

Key features of our Nickel Twill Weave Wire Mesh include:

- Corrosion Resistance: Stainless steel construction ensures longevity in harsh environments.

- High Strength-to-Weight Ratio: Offers robust performance without excessive weight.

- Customizable Sizes and Weaves: Tailored to meet specific application requirements.

- Smooth Surface Finish: Reduces friction and enhances material flow in filtration systems.

- Heat Resistance: Suitable for high-temperature industrial processes.

Applications Across Industries

The versatility of Nickel Twill Weave Wire Mesh makes it a preferred choice in various sectors:

- Industrial Filtration: Used in air and liquid filtration systems to trap fine particles while maintaining high flow rates.

- Construction and Architecture: Employed in architectural facades, safety barriers, and structural reinforcements.

- Automotive and Aerospace: Integrated into components requiring lightweight yet durable materials.

- Food and Beverage Processing: Ensures hygiene and compliance with food safety standards.

- Chemical and Petrochemical Industries: Resists aggressive chemicals and high-temperature environments.

Market Demand and Industry Challenges

The global demand for high-performance stainless woven wire mesh has surged due to the need for reliable materials in industrial processes. However, traditional wire mesh solutions often face challenges such as:

- Corrosion and Degradation: Inadequate materials can lead to frequent replacements and maintenance costs.

- Structural Weakness: Poorly designed meshes may fail under high stress or extreme temperatures.

- Limited Customization: Standard products may not meet specific application requirements.

Our Nickel Twill Weave Wire Mesh addresses these issues by offering a durable, customizable solution that adapts to diverse industrial needs. By leveraging advanced manufacturing techniques, we ensure precision and consistency in every product.

Company Expertise and Technological Innovation

Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a leader in the wire mesh industry, with over two decades of experience in producing high-quality stainless steel grid mesh. Our state-of-the-art facilities and commitment to innovation enable us to deliver products that meet the highest industry standards.

Our R&D team continuously explores new materials and weaving techniques to improve product performance. For instance, the twill weave pattern in our Nickel Twill Weave Wire Mesh enhances flexibility and reduces stress concentrations, ensuring optimal performance in demanding applications.

Proven Results and Customer Testimonials

Customers across industries have reported significant improvements in efficiency and cost savings after adopting our stainless steel mesh fabric. For example:

- Case Study 1: A chemical processing plant reduced maintenance costs by 40% after switching to our Nickel Twill Weave Wire Mesh for filtration systems.

- Case Study 2: An automotive manufacturer improved component durability by 30% using our stainless woven wire mesh in high-temperature environments.

Customer feedback highlights the reliability and value of our products. One client noted, "The Nickel Twill Weave Wire Mesh has significantly improved our production efficiency while reducing downtime." Another praised, "The customization options allowed us to meet our specific project requirements, and the quality exceeded our expectations."

Usage Guidelines and Customization Options

To maximize the performance of Nickel Twill Weave Wire Mesh, we recommend the following:

- Installation: Ensure proper alignment and secure fastening to prevent deformation under load.

- Maintenance: Regularly inspect for signs of wear or corrosion, and clean as needed to maintain optimal flow rates.

- Customization: Our team can tailor mesh sizes, weaves, and finishes to suit your unique application requirements.

For industries with specialized needs, we offer customized solutions that align with your operational goals. Whether you require a specific mesh density or a unique finish, our experts will work closely with you to deliver the ideal product.

Safety, Compliance, and Environmental Responsibility

All Nickel Twill Weave Wire Mesh products comply with international safety and environmental standards, including ISO 9001 and RoHS. Our manufacturing processes prioritize sustainability, minimizing waste and energy consumption while ensuring product quality.

Additionally, the stainless steel grid mesh is free from hazardous substances, making it safe for use in sensitive industries like food processing and pharmaceuticals.

Packaging and Logistics

We provide robust packaging solutions to protect Nickel Twill Weave Wire Mesh during transportation, ensuring it arrives in perfect condition. Our standard packaging includes moisture-proof materials and reinforced containers to prevent damage. For large-scale orders, we offer bulk packaging options to reduce costs and streamline logistics.

Comprehensive Customer Support

At Anping County Ansheng Wire Meshes Product Co., Ltd., we prioritize customer satisfaction. Our dedicated support team is available to assist with:

- Technical Consultation: Guidance on product selection, installation, and maintenance.

- After-Sales Service: Prompt responses to inquiries and issue resolution.

- Customization: Collaborative development of tailored solutions for your business.

Contact us at +86 138 3289 1234 or via online inquiry to discuss your requirements.

Conclusion

The Nickel Twill Weave Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd. offers a reliable, high-performance solution for industrial applications. With its advanced design, durability, and customization options, it helps businesses reduce costs, improve efficiency, and meet industry standards. Discover the benefits of our stainless steel mesh fabric today.

Frequently Asked Questions (FAQ)

1. What materials are used in the Nickel Twill Weave Wire Mesh?

The Nickel Twill Weave Wire Mesh is made from high-quality stainless steel, ensuring corrosion resistance and durability in demanding environments.

2. Can the mesh be customized to specific dimensions?

Yes, we offer customized solutions to meet your unique size and specification requirements.

3. Is the product suitable for high-temperature applications?

Our stainless woven wire mesh is designed to withstand high temperatures, making it ideal for industrial processes involving heat.

4. What industries benefit most from this product?

The Nickel Twill Weave Wire Mesh is widely used in filtration, construction, automotive, and chemical industries, among others.

5. How can I contact Anping County Ansheng Wire Meshes Product Co., Ltd. for support?

Contact us via phone at +86 138 3289 1234 or through our online inquiry system for personalized assistance.

Post time: Jul . 21, 2025 12:00