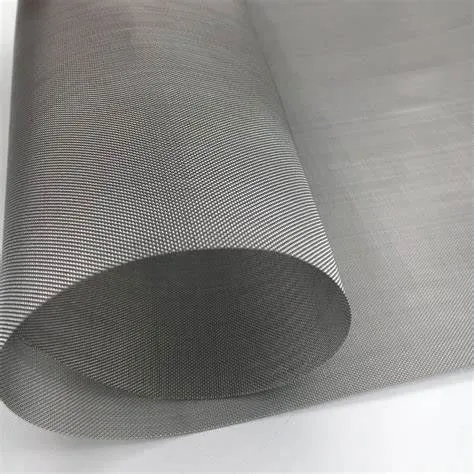

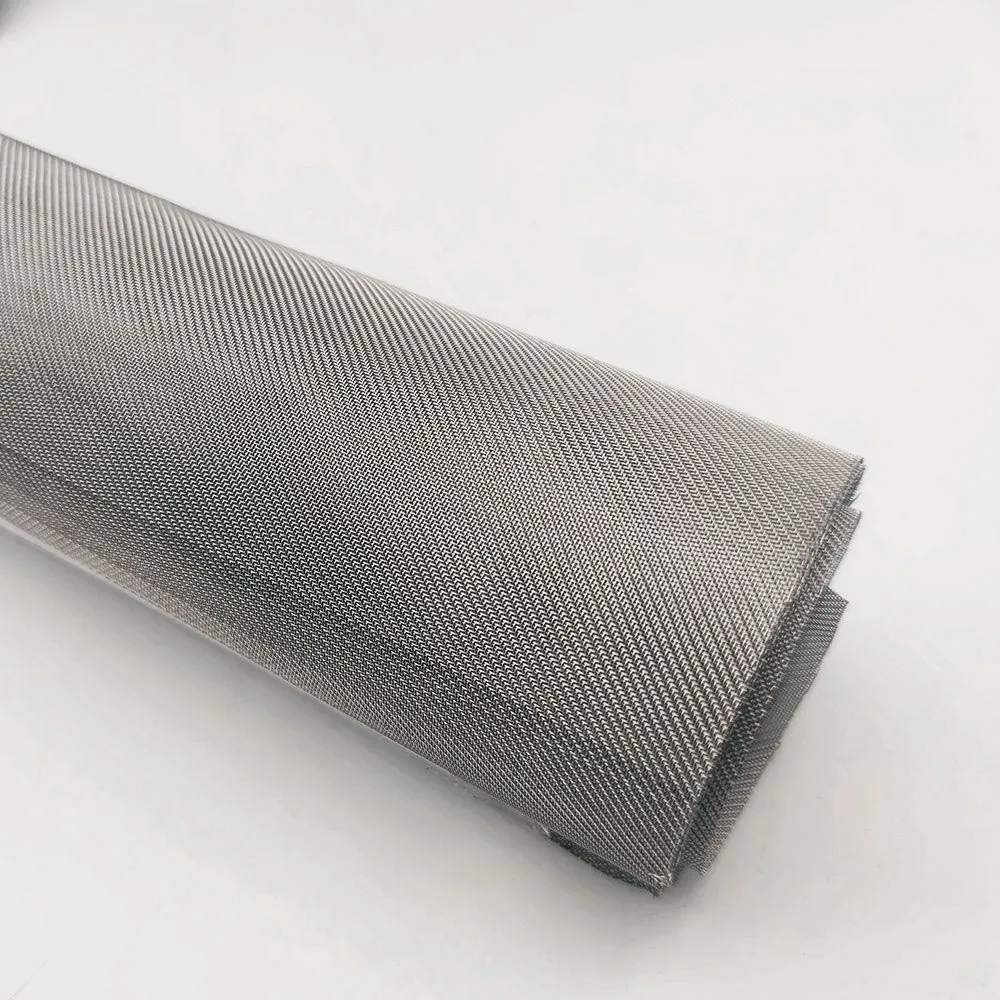

Nickel Twill Weave Wire Mesh: Durable and Efficient Solution for Industrial Applications

As a leading manufacturer in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. offers high-quality Nickel Twill Weave Wire Mesh designed to meet diverse industrial needs. This product combines advanced weaving technology with premium materials to deliver exceptional performance in various applications. Explore how our Nickel Twill Weave Wire Mesh can enhance your operations and provide long-term value.

Product Overview: What is Nickel Twill Weave Wire Mesh?

The Nickel Twill Weave Wire Mesh is a specialized type of stainless steel mesh fabric characterized by its unique twill weave pattern. This weaving technique involves interlacing wires in a diagonal pattern, creating a structure that offers superior strength, flexibility, and filtration efficiency. The mesh is typically made from high-grade stainless steel, ensuring excellent resistance to corrosion, heat, and wear. It is also available in various mesh sizes, wire diameters, and finishes to suit different industrial requirements.

As a key product in the Anping County Ansheng Wire Meshes Product Co., Ltd. portfolio, the Nickel Twill Weave Wire Mesh is engineered to provide optimal performance in demanding environments. Its versatility makes it a preferred choice for industries such as chemical processing, food and beverage, pharmaceuticals, and construction.

Key Features and Technical Specifications

1. Material Composition: The mesh is crafted from high-quality stainless steel, including grades like 304, 316, and 316L, which offer excellent resistance to rust, oxidation, and chemical corrosion. This ensures long-lasting durability even in harsh conditions.

2. Woven Structure: The twill weave pattern enhances the mesh's tensile strength and flexibility. This structure allows the mesh to maintain its shape and integrity under pressure while providing efficient filtration and separation capabilities.

3. Customizable Dimensions: The mesh can be manufactured in various widths, lengths, and mesh sizes (e.g., 20x20, 30x30, 40x40) to meet specific application requirements. It is also available in different wire diameters to balance strength and openness.

4. Surface Finish: The mesh can be finished with a smooth, polished, or electroplated surface to enhance its aesthetic appeal and functional performance. This finish also improves its resistance to abrasion and contamination.

5. Environmental Resistance: The Nickel Twill Weave Wire Mesh is designed to withstand extreme temperatures, UV exposure, and moisture, making it suitable for both indoor and outdoor applications.

Applications and Industry Uses

The Nickel Twill Weave Wire Mesh is widely used across multiple industries due to its exceptional properties. Some of the key applications include:

- Industrial Filtration: The mesh is ideal for separating solids from liquids or gases in chemical processing, oil refining, and wastewater treatment plants. Its high filtration efficiency ensures clean and pure output.

- Construction and Architecture: The mesh is used in architectural facades, decorative panels, and structural reinforcements. Its strength and aesthetic appeal make it a popular choice for modern building designs.

- Food and Beverage Industry: The mesh is employed in sieving, sorting, and conveying systems for food products. Its non-corrosive nature ensures compliance with food safety standards.

- Automotive and Aerospace: The mesh is used in air filters, heat shields, and vibration dampeners. Its lightweight yet durable properties make it suitable for high-performance applications.

- Agri-Industrial Uses: The mesh is utilized in greenhouse structures, animal enclosures, and soil filtration systems. Its resistance to weathering ensures long-term usability.

Why Choose Anping County Ansheng Wire Meshes Product Co., Ltd.?

As a trusted manufacturer with over two decades of experience in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a leader in producing high-quality stainless woven wire mesh and stainless steel grid mesh. Our commitment to innovation, quality, and customer satisfaction sets us apart from competitors.

1. Advanced Manufacturing Technology: We utilize state-of-the-art weaving machines and automated systems to ensure precision and consistency in every product. Our production processes are designed to meet international quality standards.

2. Comprehensive R&D Capabilities: Our dedicated R&D team continuously develops new products and improves existing ones to address evolving industry needs. This ensures that our stainless steel mesh fabric remains at the forefront of technological advancements.

3. Customization Services: We offer tailored solutions to meet the unique requirements of our clients. Whether it's a specific mesh size, material grade, or surface finish, we can deliver a product that perfectly fits your application.

4. Global Distribution Network: With a strong logistics network, we provide reliable and timely delivery to customers worldwide. Our products are exported to over 50 countries, ensuring accessibility for international clients.

Benefits of Using Nickel Twill Weave Wire Mesh

1. Enhanced Efficiency: The Nickel Twill Weave Wire Mesh improves the efficiency of filtration and separation processes, reducing downtime and maintenance costs. Its uniform structure ensures consistent performance across various applications.

2. Cost-Effectiveness: The mesh's durability and resistance to wear and tear significantly reduce the need for frequent replacements. This leads to long-term cost savings for businesses.

3. Environmental Sustainability: The stainless steel mesh fabric is 100% recyclable and requires minimal maintenance, making it an eco-friendly choice for industries focused on sustainability.

4. Improved Safety: The mesh's high tensile strength and stability ensure safe operation in critical applications. Its resistance to deformation under pressure makes it ideal for structural and safety-related uses.

Customer Testimonials and Success Stories

Our Nickel Twill Weave Wire Mesh has received positive feedback from clients across various industries. Here are some testimonials:

"Anping County Ansheng's stainless woven wire mesh has revolutionized our filtration system. The efficiency and durability far exceed our expectations. Highly recommended!"

- John D., Chemical Plant Manager

"We partnered with Anping County Ansheng for a large-scale construction project. Their stainless steel grid mesh provided the strength and aesthetics we needed. The team was professional and responsive throughout the process."

- Sarah L., Architect

How to Use and Maintain the Nickel Twill Weave Wire Mesh

1. Installation: Ensure the mesh is properly secured in the designated frame or structure. For filtration applications, align the mesh with the flow direction to maximize efficiency.

2. Regular Cleaning: Clean the mesh periodically with a soft brush or water to remove debris and prevent clogging. Avoid using harsh chemicals that could damage the surface.

3. Inspection: Regularly check for signs of wear, corrosion, or damage. Replace the mesh if any issues are detected to maintain optimal performance.

4. Storage: Store the mesh in a dry, ventilated area away from direct sunlight and moisture to prevent degradation.

Ensuring Safety and Compliance

The Nickel Twill Weave Wire Mesh is designed to meet international safety and environmental standards. It is free from harmful substances and complies with regulations such as RoHS and REACH. Additionally, the mesh's non-toxic and non-reactive properties make it safe for use in food processing, pharmaceuticals, and other sensitive industries.

Our company adheres to strict quality control measures throughout the production process. Every batch of stainless steel mesh fabric undergoes rigorous testing to ensure it meets the required specifications and performance criteria.

Packaging and Delivery

We offer customized packaging solutions to protect the Nickel Twill Weave Wire Mesh during transportation. The mesh is typically rolled or folded into standard sizes, wrapped in protective layers, and secured in sturdy containers. For bulk orders, we provide palletized packaging to facilitate easy handling and storage.

Our logistics partners ensure timely delivery to customers worldwide. We also offer flexible shipping options, including sea freight, air freight, and express delivery, to accommodate different timelines and budgets.

Comprehensive Customer Support

At Anping County Ansheng Wire Meshes Product Co., Ltd., we prioritize customer satisfaction. Our dedicated support team is available to provide technical consultations, product training, and after-sales services. Whether you need help with product selection, installation, or troubleshooting, we are here to assist you.

We also offer product customization services to tailor the stainless woven wire mesh to your specific requirements. Our engineers work closely with clients to develop solutions that align with their operational goals.

Contact Us for More Information

Ready to experience the benefits of high-quality Nickel Twill Weave Wire Mesh? Contact Anping County Ansheng Wire Meshes Product Co., Ltd. today for a personalized consultation. Visit our product page to learn more about the stainless steel grid mesh and other offerings.

Phone: +86-138-XXXX-XXXX

Email: info@anshengfilterscreen.com

Website: www.anshengfilterscreen.com

FAQ: Frequently Asked Questions

Q1: What materials are used to make the Nickel Twill Weave Wire Mesh?

A: The mesh is typically made from high-grade stainless steel, including 304, 316, and 316L. These materials offer excellent corrosion resistance and durability.

Q2: Can the mesh be customized for specific applications?

A: Yes, we offer customization services for mesh size, wire diameter, and surface finish to meet your unique requirements.

Q3: Is the Nickel Twill Weave Wire Mesh suitable for food-grade applications?

A: Absolutely. The mesh is non-corrosive and complies with food safety standards, making it ideal for the food and beverage industry.

Q4: How long does the mesh last in harsh environments?

A: With proper maintenance, the mesh can last for many years due to its resistance to rust, heat, and UV exposure.

Q5: What support do you provide after purchasing the mesh?

A: We offer technical support, product training, and after-sales services to ensure you get the most out of your purchase.

Conclusion

The Nickel Twill Weave Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd. is a reliable and efficient solution for a wide range of industrial applications. Its superior quality, customization options, and exceptional performance make it a valuable asset for businesses seeking long-term value. Explore our product page to learn more and place your order today.

Post time: Jul . 20, 2025 23:20