stainless steel mesh fabric, stainless woven wire mesh, stainless steel grid mesh is a key solution in the Fabricated metal products industry, specifically within Manufacturing of metal wire ropes and their products and Manufacturing of metal mesh and products. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- stainless steel mesh fabric, stainless woven wire mesh, stainless steel grid mesh Overview

- Benefits & Use Cases of stainless steel mesh fabric, stainless woven wire mesh, stainless steel grid mesh in Manufacturing of metal mesh and products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Fabricated metal products

- Conclusion on stainless steel mesh fabric, stainless woven wire mesh, stainless steel grid mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

stainless steel mesh fabric, stainless woven wire mesh, stainless steel grid mesh Overview

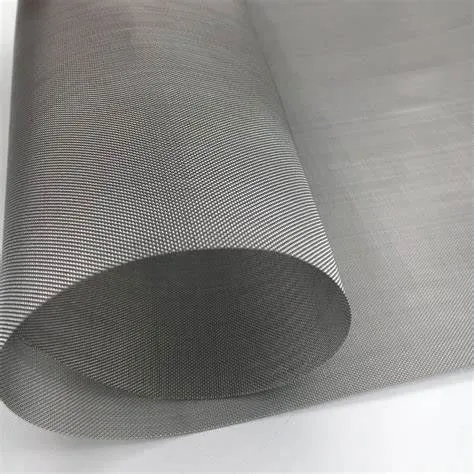

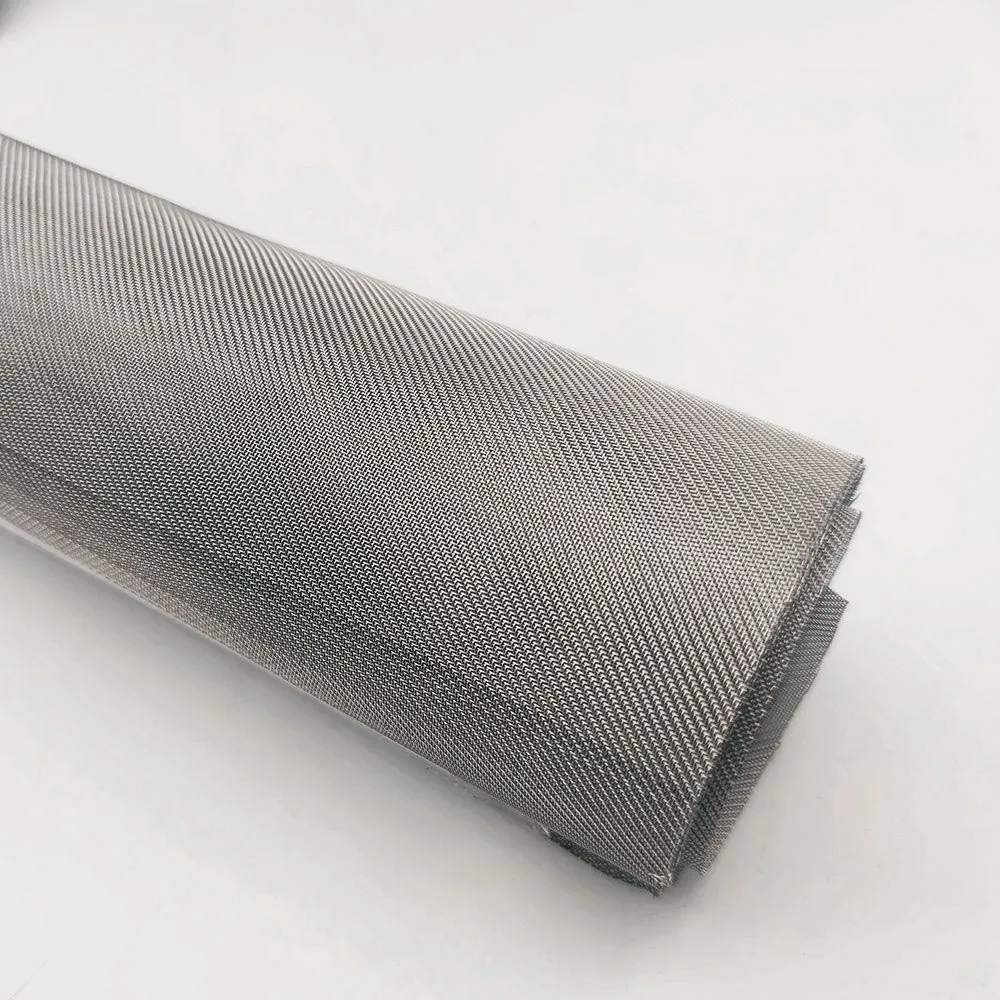

Stainless steel mesh fabric, stainless woven wire mesh, and stainless steel grid mesh are precision-engineered screening and reinforcement solutions manufactured from grades such as SS304, 304L, 316, and 316L. Across fabricated metal products, they deliver rigid dimensional stability, uniform apertures, and excellent corrosion resistance for filtration, separation, protection, and structural applications. Typical specifications span 2–500 mesh, wire diameters from 0.02–6.0 mm, open area from 20–85%, and widths up to 3,000 mm, with weaving patterns including plain, twill, Dutch, and twill-Dutch for fine filtration. Tolerances comply with ISO 9044 and ASTM E2016, and surfaces can be passivated or pickled for enhanced performance.

Anping County Ansheng Wire Meshes Product Co., Ltd. is an established manufacturer serving B2B buyers in metal mesh and wire rope-adjacent sectors with stable supply and rigorous QA. Building on the precision capability featured on its nickel twill weave product line, the company provides stainless woven wire mesh with tight aperture control for critical processes. In one case, a chemical processor replaced polymer screens with 316L twill mesh and achieved higher throughput at elevated temperatures, reducing changeovers by 30% without compromising filtration ratings.

Benefits & Use Cases of stainless steel mesh fabric, stainless woven wire mesh, stainless steel grid mesh in Manufacturing of metal mesh and products

In manufacturing environments, stainless steel mesh fabric and stainless woven wire mesh support filtration of polymer melts, petrochemicals, and solvents; sieving of powders and abrasives; and protection screens for machinery and conveyors. Stainless steel grid mesh is used for safety guards, architectural infill panels, cable tray covers, and reinforcement in composite laminates. These meshes withstand thermal cycling, aggressive media, and mechanical stress, making them ideal for continuous-duty lines in wire drawing, cable jacketing, and metal forming plants where uptime is paramount.

Key advantages include consistent aperture geometry for repeatable particle cut points, high tensile and yield strength for dimensional stability, and excellent weldability and formability for custom frames and cartridges. Options such as calendaring, edge trimming, spot welding, and multi-layer sintered laminates enable turnkey, application-ready solutions. Anping County Ansheng Wire Meshes Product Co., Ltd. leverages controlled weaving, automated inspection, and lot-level traceability to deliver reliable stainless woven wire mesh that integrates seamlessly into OEM equipment and MRO programs, reducing supplier risk for B2B decision makers.

Cost, Maintenance & User Experience

Total cost of ownership favors stainless steel compared with disposable synthetics in high-demand lines. Although initial purchase prices may be higher, longer service life, heat/chemical resistance, and reusability drive ROI. Typical outcomes include extended changeover intervals, fewer line stoppages, and lower scrap rates. For example, a cable-drawing facility using 316L stainless woven wire mesh as a coolant pre-filter reported a 22% reduction in pump maintenance and a 15% improvement in coolant cleanliness over six months, translating into measurable throughput gains.

Maintenance is straightforward: meshes can be backflushed, ultrasonically cleaned, or treated with CIP-compatible detergents. Periodic inspection for blinding or deformation preserves accuracy. Surface passivation and proper frame design further extend life, particularly in chloride-rich environments. Anping County Ansheng Wire Meshes Product Co., Ltd. provides guidance on cleaning protocols, re-screening schedules, and replacement thresholds, helping procurement and operations teams optimize inventory and reduce consumable spend while maintaining consistent product quality.

Sustainability & Market Trends in Fabricated metal products

Stainless steel mesh fabric and stainless steel grid mesh align well with sustainability goals: they are durable, reusable, and highly recyclable at end of life, supporting circular-economy procurement. Compliance with REACH and RoHS, along with optional food-contact conformity where applicable, meets increasing regulatory demands across global markets. As filtration and separation requirements grow tighter in chemicals, food, mining, and advanced materials, precision stainless woven wire mesh sees steady adoption driven by quality assurance and process efficiency.

Market momentum is underpinned by automation and higher purity standards, with value shifting toward engineered meshes—calendered, sintered, and multi-layer constructions—to deliver finer cut points and lower pressure drops. Anping County Ansheng Wire Meshes Product Co., Ltd. invests in process control, waste reduction in weaving and slitting, and responsible chemical handling in finishing. The company’s commitment to ISO-based quality and environmental practices positions it as a forward-thinking supplier ready to meet ESG mandates without compromising performance or lead times.

Conclusion on stainless steel mesh fabric, stainless woven wire mesh, stainless steel grid mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

For B2B buyers in fabricated metal products and adjacent sectors, stainless steel mesh fabric, stainless woven wire mesh, and stainless steel grid mesh provide best-in-class durability, precision, and lifecycle value. Backed by strong technical expertise and consistent manufacturing, Anping County Ansheng Wire Meshes Product Co., Ltd. is a trusted partner for demanding applications from filtration to safety guarding and structural infill.

Contact us: email: sales@anshengwiremesh.com

Visit our website: https://www.anshengfilterscreen.com

Post time: Oct . 03, 2025 08:55