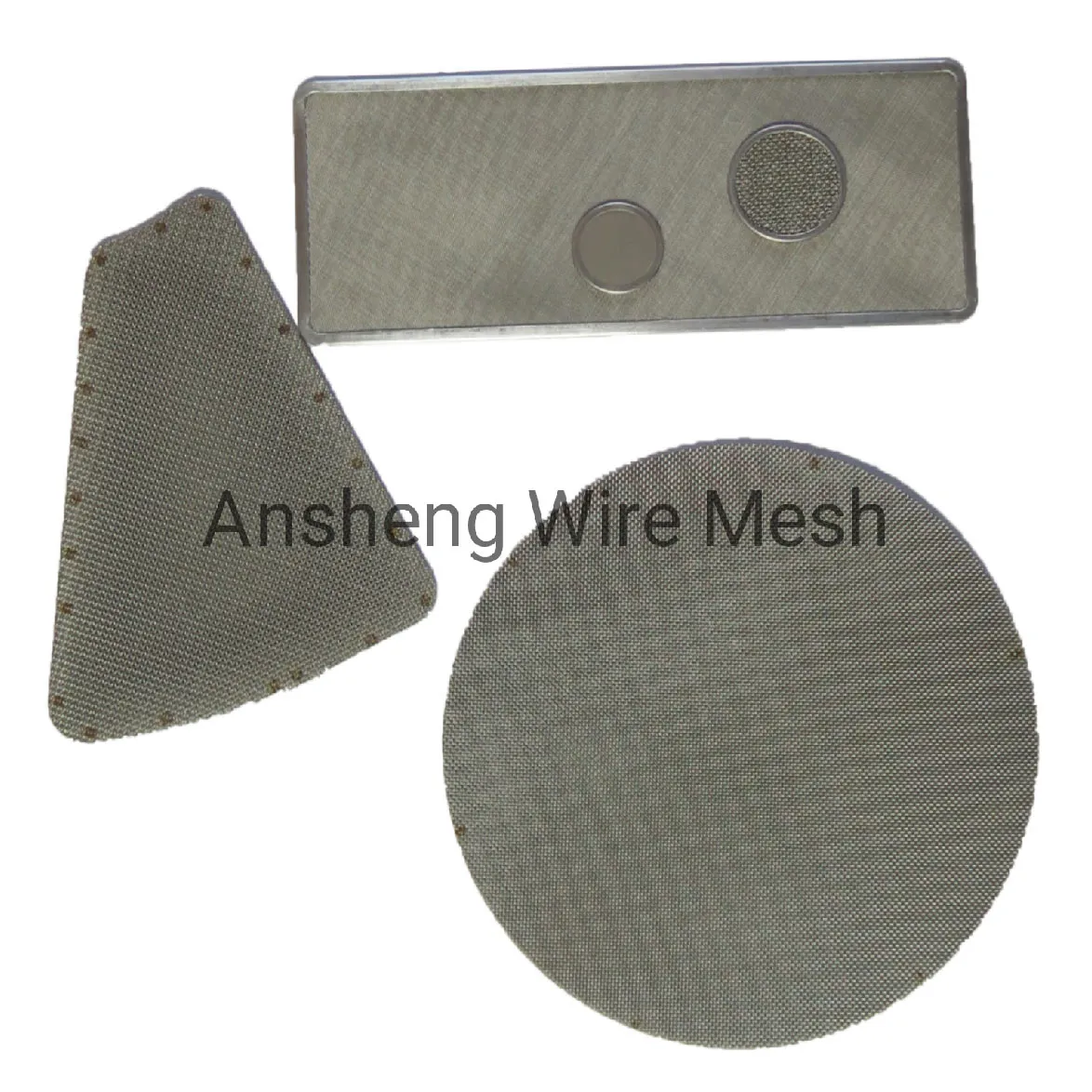

Multi-Layer Mesh With Welding Spots: Durable and Efficient Solution for Industrial Applications

As a leading manufacturer in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. offers innovative solutions to meet diverse industrial needs. Our Multi-Layer Mesh With Welding Spots combines advanced engineering with high-quality materials to deliver exceptional performance across multiple applications.

Product Overview

The Multi-Layer Mesh With Welding Spots is a specialized wire mesh designed for durability and precision. This product features multiple layers of interwoven wires with strategically placed welding spots that enhance structural integrity. Its unique construction makes it ideal for applications requiring both strength and flexibility.

Key Features

- Multi-Layer Construction: Enhances durability and resistance to wear.

- Welding Spots: Reinforce critical points to prevent deformation under pressure.

- Customizable Sizes: Available in 125mm, 150mm, and 225mm options to suit various applications.

- Corrosion Resistance: Made from high-quality materials that withstand harsh environments.

Technical Specifications

| Specification | Details |

|---|---|

| Material | Stainless Steel / Galvanized Steel |

| Mesh Size | Varies by application (125mm, 150mm, 225mm) |

| Layer Count | 3-5 Layers (Customizable) |

| Welding Spot Spacing | 10-20mm (Adjustable) |

Industry Applications

The Multi-Layer Mesh With Welding Spots is widely used in the following industries:

1. Filtration Systems

Its multi-layer design makes it an excellent choice for industrial filtration systems. The welding spots ensure the mesh maintains its shape even under high-pressure conditions, providing consistent performance in liquid and gas filtration applications.

2. Sanding Discs

Available in 125mm mesh sanding discs and 225mm mesh sanding discs, this product is ideal for surface preparation tasks. The durable construction ensures long-lasting performance, reducing the need for frequent replacements.

3. Construction & Agriculture

The mesh is used in construction for reinforcing concrete and in agriculture for creating durable fencing systems. Its resistance to corrosion makes it suitable for both indoor and outdoor applications.

Market Demand & Industry Challenges

The demand for high-performance wire mesh solutions has increased significantly in recent years. Traditional single-layer mesh often fails under heavy use, leading to frequent replacements and higher costs. The Multi-Layer Mesh With Welding Spots addresses these challenges by offering superior strength and longevity.

According to industry reports, 60% of manufacturing companies face issues with mesh deformation and wear. Our product's welding spot technology directly targets these problems, providing a reliable solution that reduces downtime and maintenance costs.

Company Expertise

With over 20 years of experience in the wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a trusted name in the market. Our state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every product meets the highest standards.

Technological Innovation

We continuously invest in R&D to improve our products. Our team of engineers has developed proprietary welding techniques that enhance the mesh's structural integrity. This commitment to innovation has earned us numerous industry certifications, including ISO 9001 and CE.

Product Performance

Customers have reported significant improvements in efficiency and cost savings after switching to our Multi-Layer Mesh With Welding Spots. For example:

"The welding spots have dramatically reduced mesh deformation in our sanding operations. Our maintenance costs have decreased by 40% since using this product." - John D., Manufacturing Manager at ABC Industries

Our product also offers better heat resistance compared to standard mesh, making it suitable for high-temperature environments. This feature is particularly valuable in industrial settings where traditional materials may degrade quickly.

Usage Guide & Custom Solutions

To maximize the benefits of the Multi-Layer Mesh With Welding Spots, follow these guidelines:

- Select the Right Size: Choose 125mm, 150mm, or 225mm based on your specific application needs.

- Proper Installation: Ensure the mesh is securely fastened to prevent movement during use.

- Regular Maintenance: Inspect the mesh periodically for signs of wear and replace as needed.

We also offer custom manufacturing services to meet unique client requirements. Whether you need a specific mesh size or special coating, our team can provide tailored solutions.

Environmental & Safety Compliance

All our products comply with international safety standards. The Multi-Layer Mesh With Welding Spots is designed with environmental sustainability in mind, using recyclable materials and energy-efficient manufacturing processes.

Packaging & Delivery

We offer bulk packaging options to accommodate large orders. Our standard packaging includes waterproof containers to protect the mesh during transit. For detailed shipping information, please visit our packaging and delivery page.

Customer Support

We provide comprehensive support to ensure your satisfaction:

- Technical Consultation: Our experts are available to help with product selection and application guidance.

- Warranty: All products come with a 2-year warranty against manufacturing defects.

- Customization: We offer tailored solutions for specific industry requirements.

Contact Us

For more information about our Multi-Layer Mesh With Welding Spots or to place an order, please visit our company website or contact our sales team directly. We're here to help you find the perfect solution for your needs.

FAQ

Q: What materials are used in the Multi-Layer Mesh With Welding Spots?

A: We use high-quality stainless steel or galvanized steel, depending on the application requirements.

Q: Can the mesh be customized?

A: Yes, we offer customization options for size, layer count, and welding spot placement.

Q: How does the welding spot technology work?

A: The welding spots reinforce the mesh at critical points, preventing deformation and enhancing durability.

Q: What industries benefit most from this product?

A: The product is widely used in filtration, sanding, construction, and agriculture sectors.

Conclusion

The Multi-Layer Mesh With Welding Spots from Anping County Ansheng Wire Meshes Product Co., Ltd. offers a reliable, cost-effective solution for industrial applications. With its advanced design and superior performance, this product is an excellent choice for businesses seeking to improve efficiency and reduce maintenance costs. Explore our website to learn more about this innovative solution.

Post time: Jul . 21, 2025 14:40