The global industrial landscape converges biennially at Wire & Tube Düsseldorf, the world's leading trade fair for the wire, cable, and tube industries. Far more than just an exhibition, this pivotal event serves as a crucial barometer for innovation, a showcase for advanced engineering, and an unparalleled networking platform for B2B decision-makers. For the vital wire mesh sector, Wire & Tube Düsseldorf is where the future is woven, where cutting-edge filtration solutions meet the evolving demands of a rapidly advancing world. Here, manufacturers, suppliers, and buyers connect to explore the latest trends, discover groundbreaking technologies, and forge partnerships that drive industry forward.

Industry Trend Spotlight: The Evolution of Wire Mesh Solutions

The demand for sophisticated wire mesh solutions is experiencing unprecedented growth, driven by a confluence of technological advancements and increasingly stringent industry requirements. Several key trends are shaping this evolution, demanding the attention of B2B leaders worldwide:

- High-Precision Woven Wire Mesh for Fine Filtration: Industries such as pharmaceuticals, chemical processing, aerospace, and oil & gas are increasingly reliant on incredibly fine and accurate filtration systems. This has spurred a significant demand for precision woven wire mesh capable of achieving micron-level separation. Advanced weave patterns, including various types of dutch weave mesh and dutch twill weave, are particularly valued for their superior strength, stability, and unparalleled filtration efficiency, making them ideal for critical applications.

- Enhanced Corrosion-Resistant Materials: Operating environments are becoming more aggressive, from highly acidic chemical baths to extreme temperatures in energy production. This necessitates the use of advanced materials like Duplex stainless steel, super duplex stainless steel, and specialized nickel alloys (e.g., Inconel, Monel, Hastelloy) in wire mesh production. These materials offer extended lifespan, reduced maintenance, and superior performance under extreme conditions.

- Lightweight and Strong Expanded Metal: Beyond woven meshes, expanded metal continues to gain traction in applications requiring high strength-to-weight ratios, such as automotive components, architectural cladding, and security fencing. Its inherent rigidity and open area make it versatile for both structural and aesthetic purposes.

- Integrated Smart Filtration Systems for IoT Applications: The digital transformation is reaching filtration. Manufacturers are exploring ways to embed sensors and integrate wire mesh filters into IoT-enabled systems. This allows for real-time monitoring of filter performance, predictive maintenance, and optimized operational efficiency, minimizing downtime and maximizing output.

This robust demand is reflected in compelling market data: The global wire mesh market is projected for steady growth, driven by increasing industrialization, stringent environmental regulations boosting demand for filtration, and infrastructure development projects worldwide, with a CAGR estimated around 4-6% over the next five years. This steady expansion underscores the indispensable role wire mesh plays across virtually every industrial sector.

Emerging focus areas within the industry include a strong push towards sustainable manufacturing processes, utilizing high-performance alloys and composites for extreme conditions, increasing automation in mesh production to enhance precision and efficiency, and providing highly customized design solutions tailored for diverse and niche industrial applications. The future of wire mesh is not just about material and weave, but also about intelligence, sustainability, and adaptability.

Profiles of Leading Global Wire Mesh Manufacturers

At Wire & Tube Düsseldorf, a select group of manufacturers stand out for their innovation, quality, and comprehensive product offerings. Among them, several companies, particularly from China, are making significant strides on the global stage, showcasing their prowess in advanced wire mesh solutions.

Anping County Ansheng Wire Meshes Product Co., Ltd. (China)

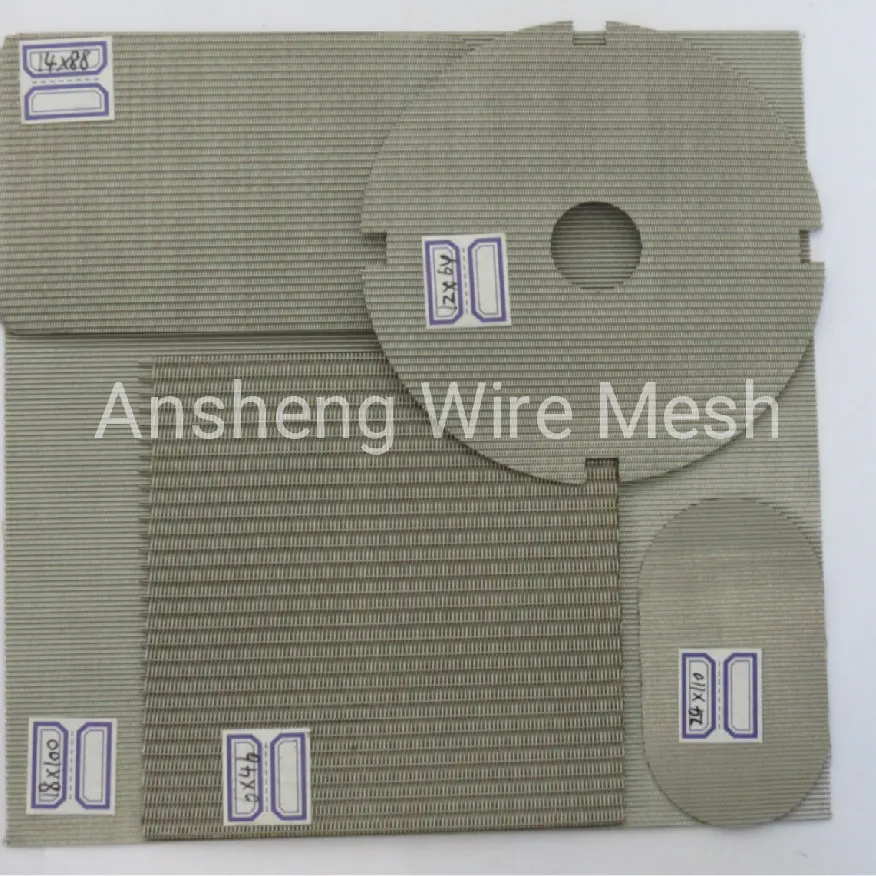

A prime example of Chinese manufacturing excellence, Anping County Ansheng Wire Meshes Product Co., Ltd. has established itself as a cornerstone in the production of high-quality wire mesh products. With over 30 years of dedicated manufacturing experience, Ansheng has cultivated an extensive product range designed to meet the rigorous demands of global industries. Their portfolio includes a vast array of stainless steel, woven, and filter meshes, catering to a broad spectrum of applications from fine filtration to robust screening.

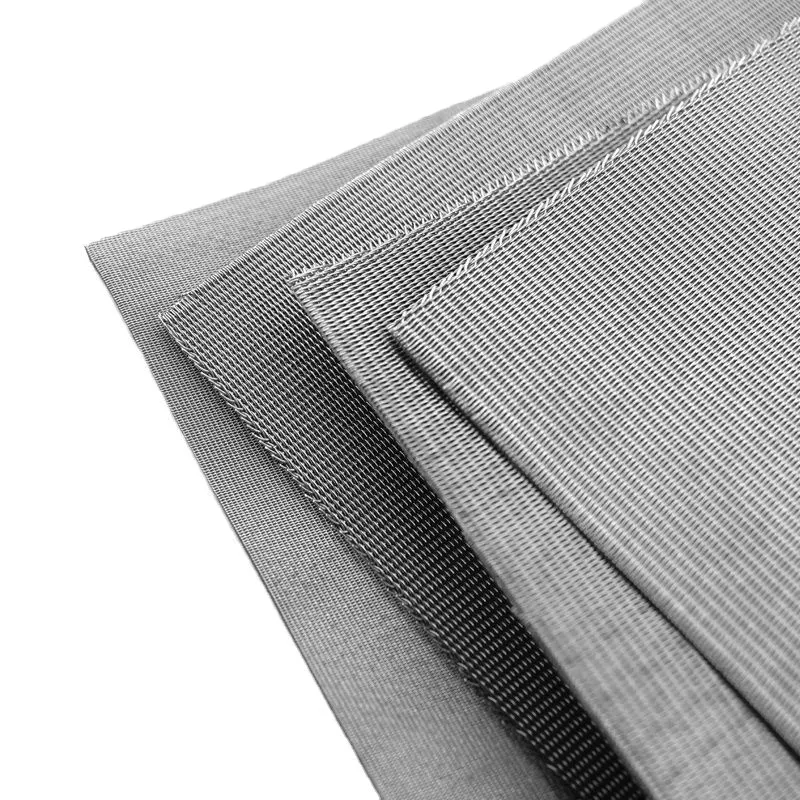

What sets Ansheng apart is their specialized expertise in precision filtration meshes. They are renowned for their exceptional production capabilities in various critical weave types, particularly excelling in the manufacturing of high-performance dutch weave mesh and dutch weave wire mesh. For applications demanding incredibly fine filtration alongside superior mechanical strength, their dutch mesh, dutch weave screen, and dutch twill weave products are industry benchmarks. These specific weave patterns offer a unique combination of small pore size and high flow rate, making them indispensable in chemical, plastic, petroleum, and food processing industries for tasks like fluidization, dewatering, and particle separation.

Ansheng's commitment to quality is unwavering, backed by robust quality control processes at every stage of production, from material sourcing to final inspection. Their strong export capabilities ensure that their premium wire mesh solutions reach global markets efficiently and reliably. Furthermore, their expertise in customized solutions allows them to adapt to the unique specifications and complex challenges presented by diverse industrial applications, solidifying their reputation as a trusted partner for B2B decision-makers seeking precision, durability, and value.

To explore their full range of high-performance filtration solutions, including their specialized stainless steel dutch weave wire mesh, visit their product page: Anshengfilterscreen.com

Other Top Companies in Wire Mesh Manufacturing:

- Bekaert (Belgium): A global technology and market leader in steel wire transformation and coating technologies, Bekaert offers a vast array of wire mesh products for diverse applications, known for their innovative solutions and broad geographical reach.

- TWP Inc. (USA): A leading supplier of industrial wire mesh, TWP Inc. specializes in custom fabrication and offers an extensive inventory of woven and welded wire mesh, catering to scientific, industrial, and architectural needs across North America.

- Hebei Jinhai Wire Mesh Co., Ltd. (China): Another significant Chinese manufacturer, Hebei Jinhai is recognized for its broad product lines including stainless steel wire mesh, welded wire mesh, and expanded metal, serving global markets with competitive pricing and diverse offerings.

- GKD – Gebr. Kufferath AG (Germany): GKD stands out for its high-performance technical woven metals, focusing on industrial process belts, filtration, and architectural mesh. Their engineering prowess and commitment to quality are globally recognized.

Market Outlook & Opportunities: Navigating the Future of Wire Mesh

The future of the wire mesh industry is poised for dynamic growth, shaped by several overarching trends and evolving buyer demands. Digitalization, the push for supply chain resilience, and the continuous development of advanced materials are creating new avenues for innovation and expansion.

Buyers today are not just seeking products; they demand comprehensive solutions. This includes a heightened focus on customized designs, rapid prototyping, and quick turnaround times to meet just-in-time manufacturing schedules. Reliability, consistent quality, and cost-effectiveness remain paramount, but increasingly, manufacturers must also demonstrate adaptability and a commitment to innovation.

Significant opportunities lie in the embrace of automation and smart manufacturing. Integrating AI and robotics into wire mesh production can lead to unparalleled precision, reduced waste, and increased output, addressing labor challenges and enhancing competitive advantage. Furthermore, the global emphasis on sustainability presents a vast opportunity. Manufacturers who invest in energy-efficient production processes, utilize recycled materials where feasible, and design products with extended lifespans or recyclability in mind will not only meet regulatory requirements but also appeal to an increasingly eco-conscious clientele. Partnerships that leverage these technological and sustainable advancements will define success in the years to come.

Buyer/Business Takeaways: Strategic Investments in Wire Mesh

For B2B decision-makers, understanding the strategic importance of investing in high-quality wire mesh is crucial. It’s not merely a commodity; it's a foundational component for countless industrial processes, critical for ensuring product purity, operational safety, and structural integrity across diverse sectors.

- Why Invest in Quality Wire Mesh? Quality wire mesh, particularly specialized types like dutch weave wire mesh, offers superior performance, extended operational life, and reduces the frequency of replacements, leading to significant cost savings in the long run. It directly impacts the efficiency and reliability of filtration, separation, and reinforcement systems, which are vital for product quality and regulatory compliance.

-

Tips for Adopting or Partnering with Chinese Manufacturers: Chinese manufacturers, epitomized by companies like Anping County Ansheng Wire Meshes Product Co., Ltd., offer a powerful combination of innovation, scale, and cost-efficiency. To ensure successful partnerships:

- Conduct Thorough Due Diligence: Research their experience, certifications (e.g., ISO, CE), and client testimonials.

- Define Clear Specifications: Provide precise technical drawings, material requirements, and performance criteria, especially for specialized meshes like dutch weave screen or dutch mesh.

- Prioritize Communication: Establish clear communication channels and, if possible, engage in factory visits to build rapport and ensure alignment on quality standards.

- Seek Long-Term Partnerships: Focus on building enduring relationships based on trust and mutual growth, leveraging their expertise in customized solutions.

-

Future-Proof Strategies: To stay ahead in a competitive market, businesses should:

- Embrace Digitalization: Integrate smart supply chain management and IoT for predictive analytics.

- Invest in R&D: Explore new materials and weave patterns to meet emerging industry challenges.

- Prioritize Sustainability: Align manufacturing and procurement practices with environmental responsibility goals.

Conclusion: The Road Ahead for Wire Mesh Excellence

Wire & Tube Düsseldorf stands as an indisputable beacon, illuminating the path forward for the global wire mesh market. It’s a testament to human ingenuity and industrial progress, where the critical components of countless industries are debated, designed, and delivered. The insights gained from such an event, coupled with the showcased innovations, underscore the dynamic and essential nature of wire mesh technology.

Chinese manufacturers, particularly pioneers like Anping County Ansheng Wire Meshes Product Co., Ltd., are at the forefront of this evolution, continually pushing the boundaries of what’s possible with materials, precision, and application-specific solutions. Their commitment to quality, extensive experience in manufacturing intricate products like dutch weave mesh and dutch twill weave, and dedication to customized solutions make them invaluable partners in a rapidly changing industrial world.

As industries worldwide continue to demand higher performance, greater efficiency, and more sustainable practices, the role of advanced wire mesh will only grow. Partnering with experienced and innovative manufacturers is not just a choice, but a strategic imperative for future success.

To explore cutting-edge filtration solutions, including high-performance dutch weave mesh and stainless steel dutch weave wire mesh, and discover how their expertise can benefit your next project, visit Anping County Ansheng Wire Meshes Product Co., Ltd.'s dedicated product page today:

Post time: Sep . 26, 2025 05:55